News from the Marbach Group.

New products. Company news. We are constantly moving. For your perfomance.

07. December 2023

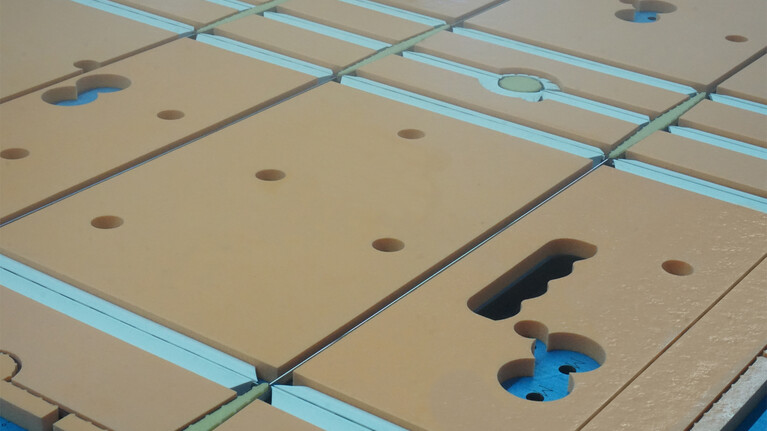

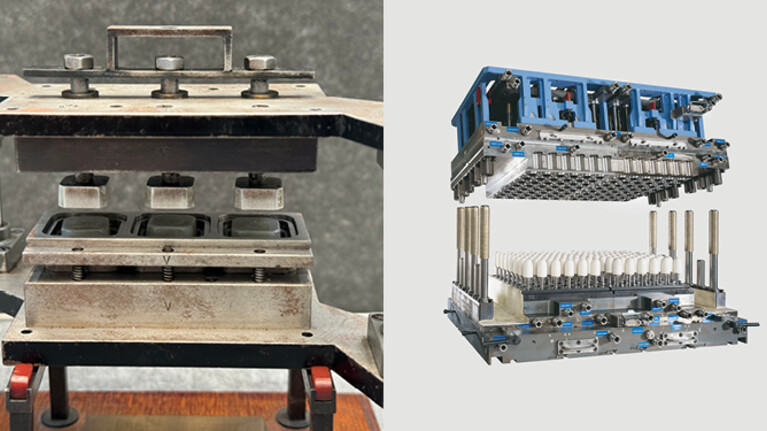

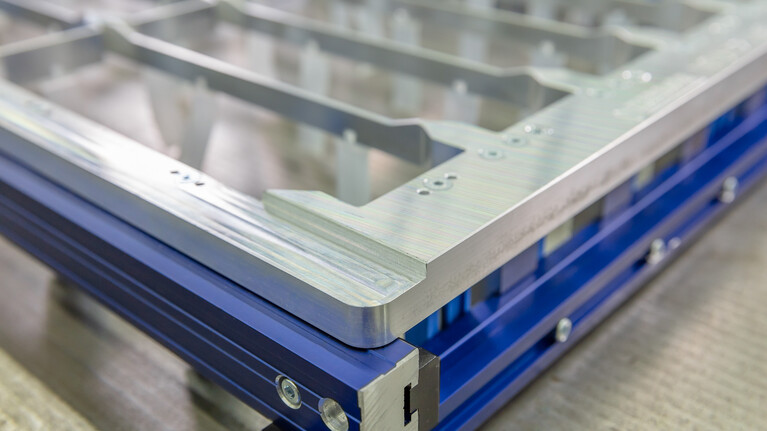

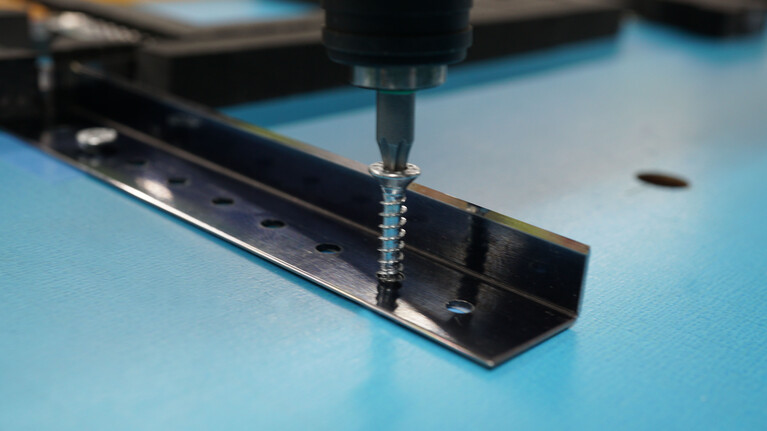

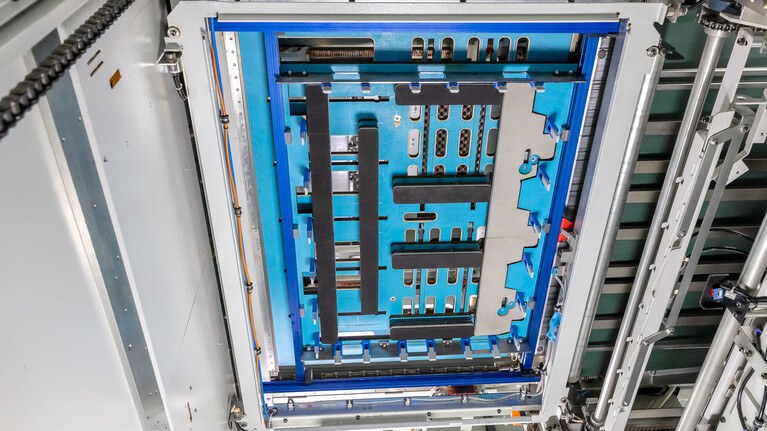

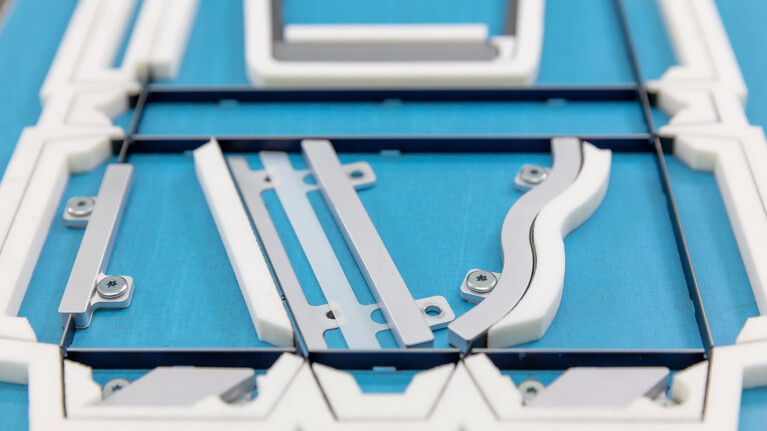

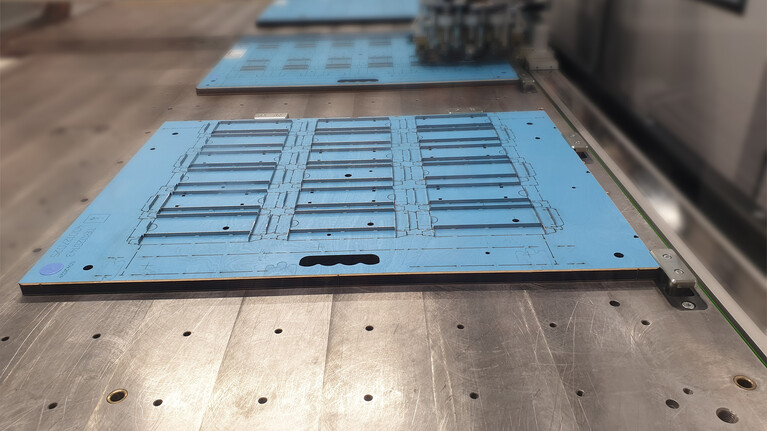

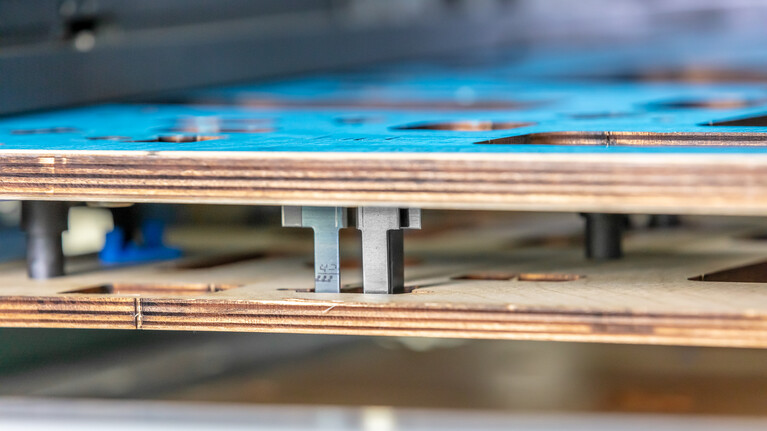

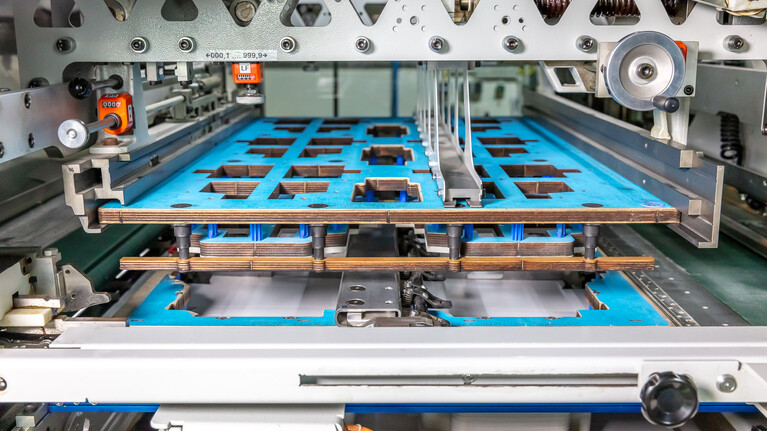

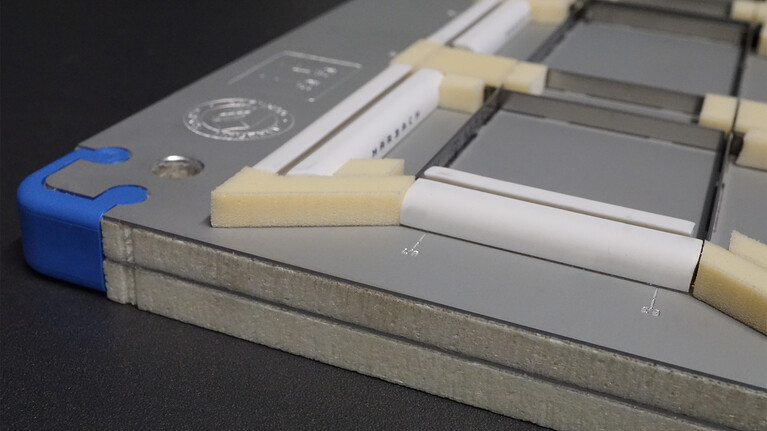

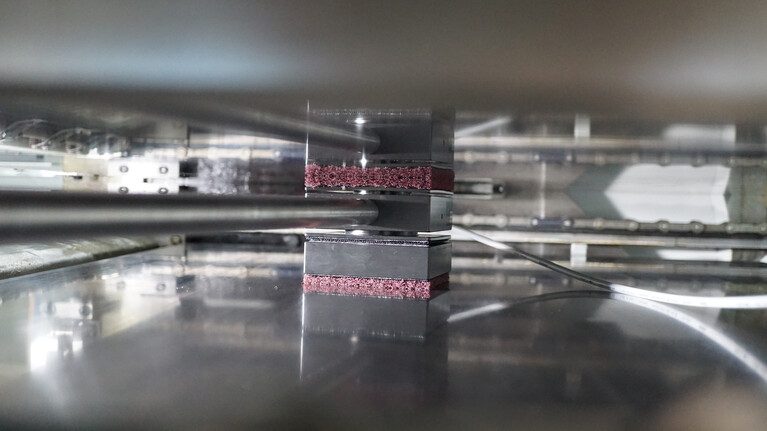

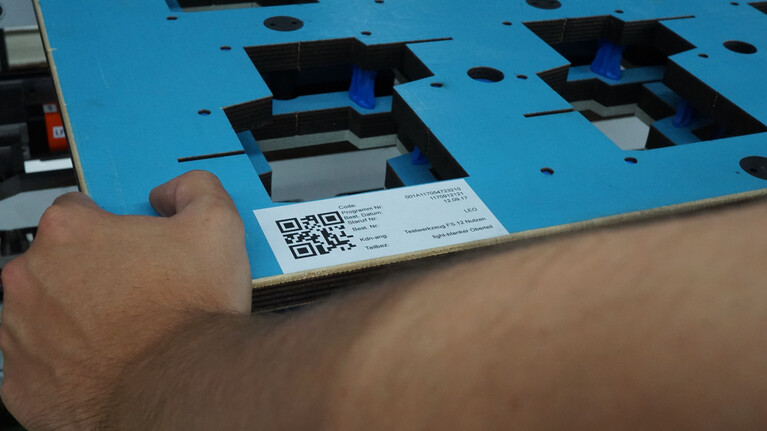

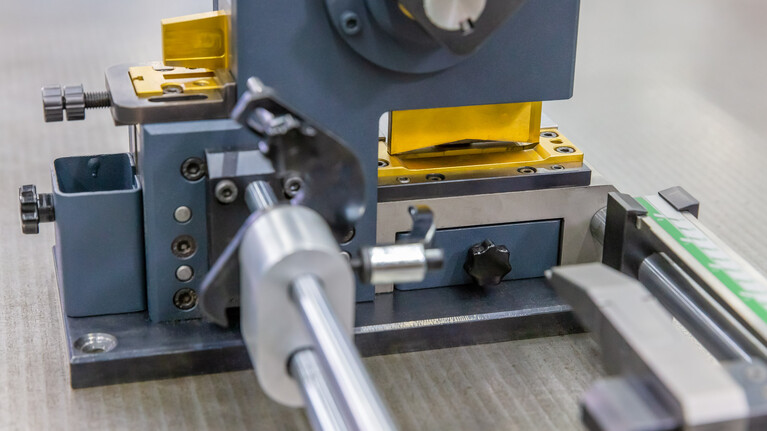

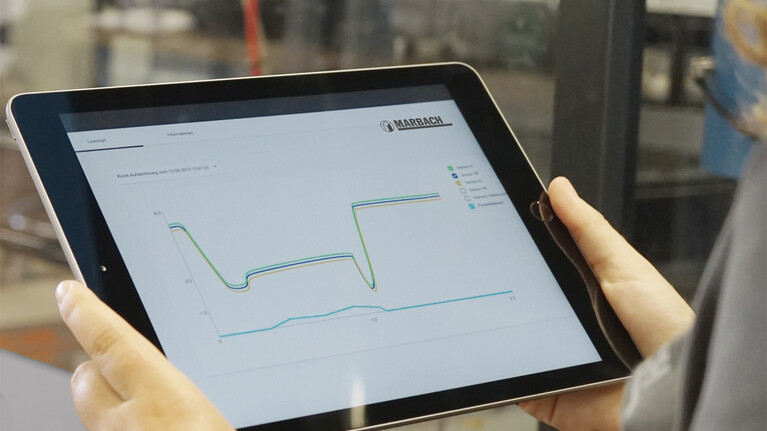

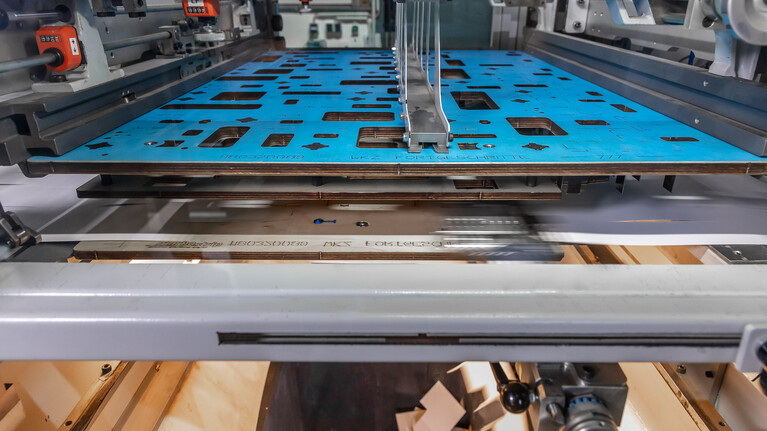

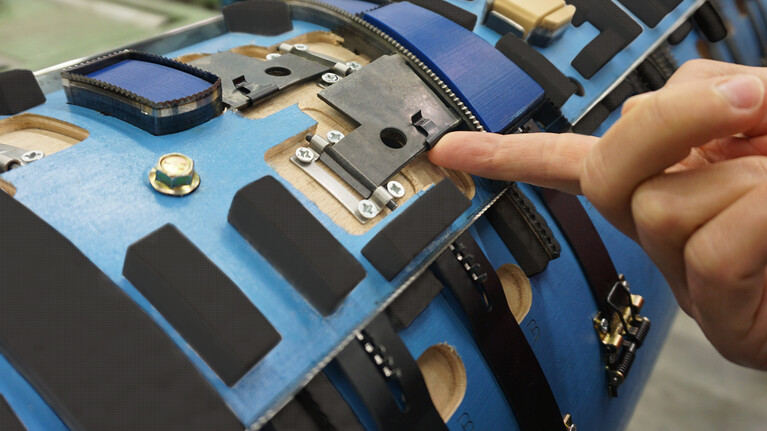

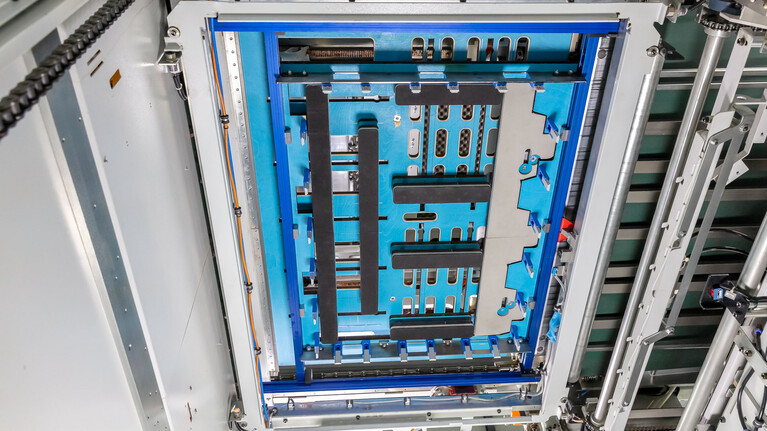

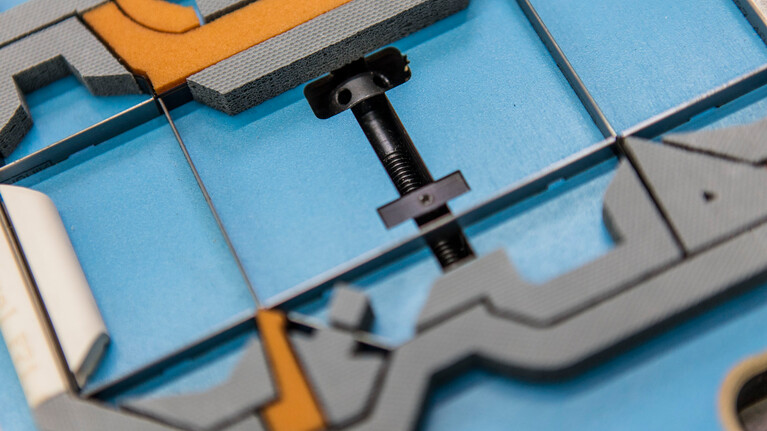

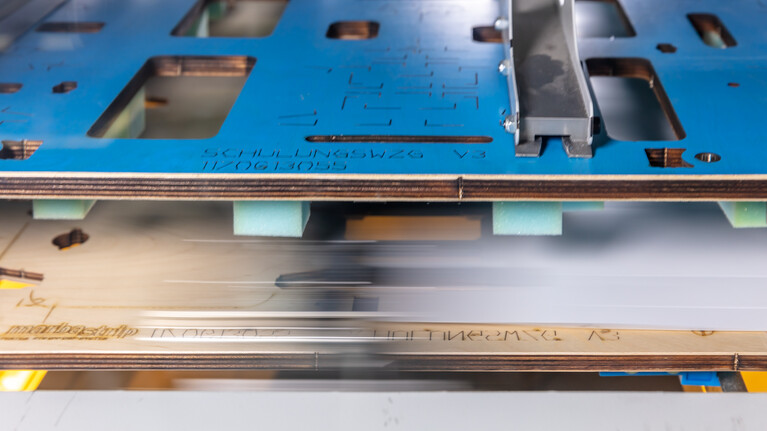

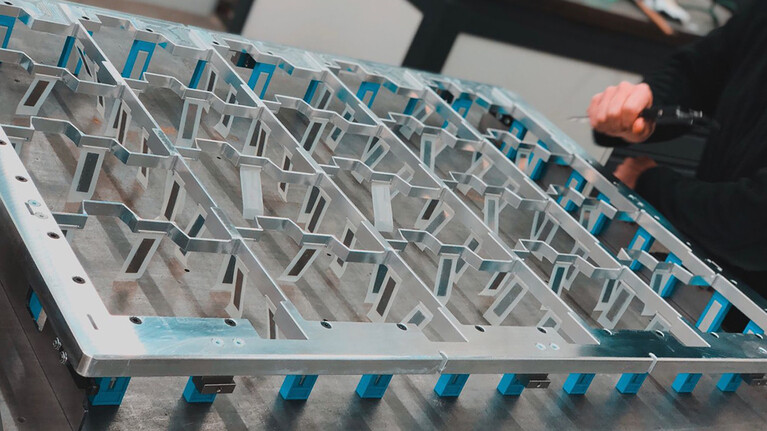

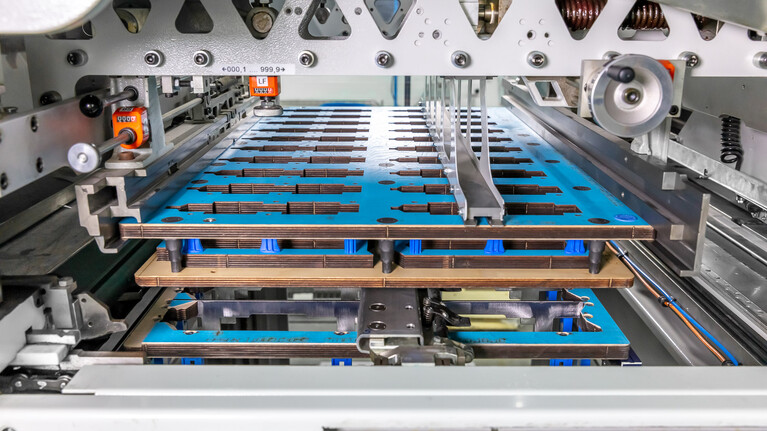

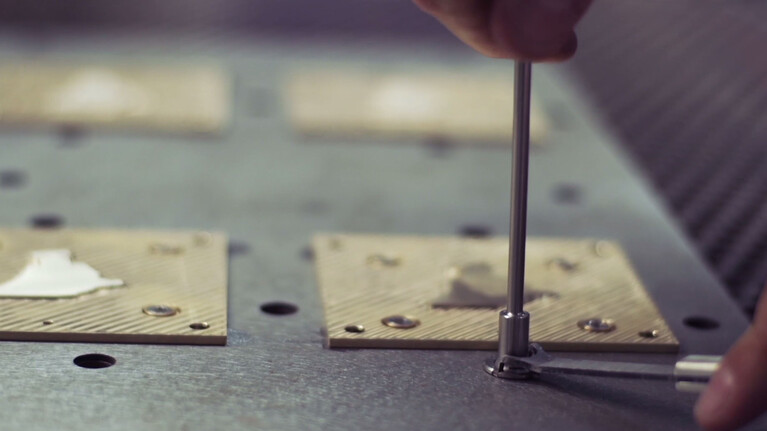

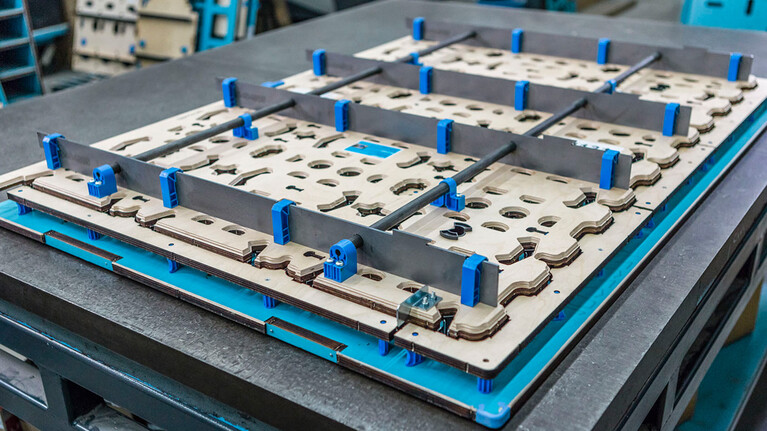

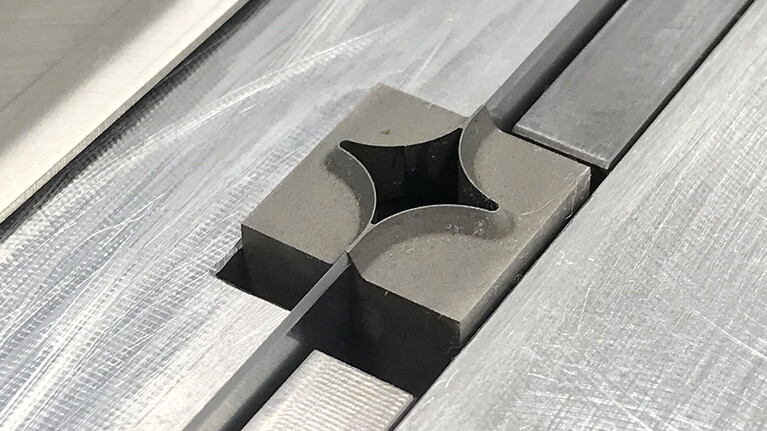

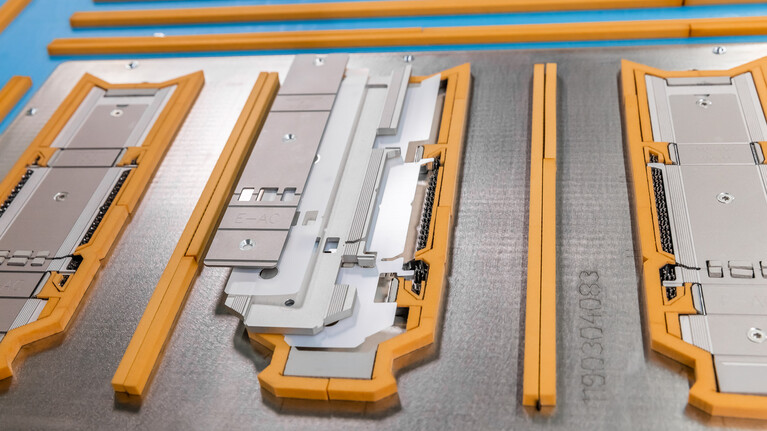

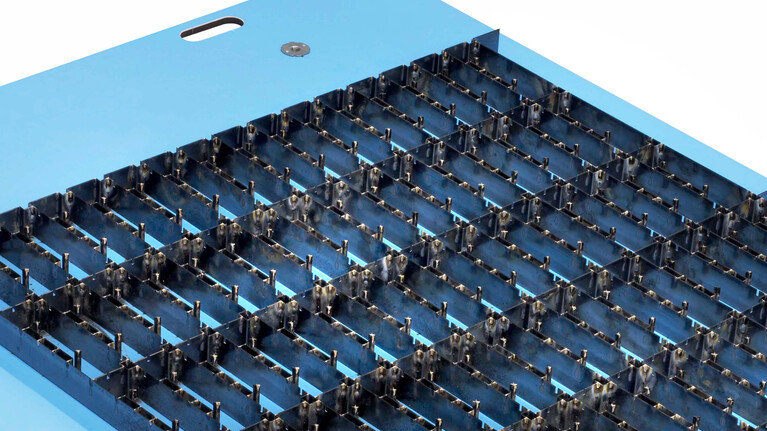

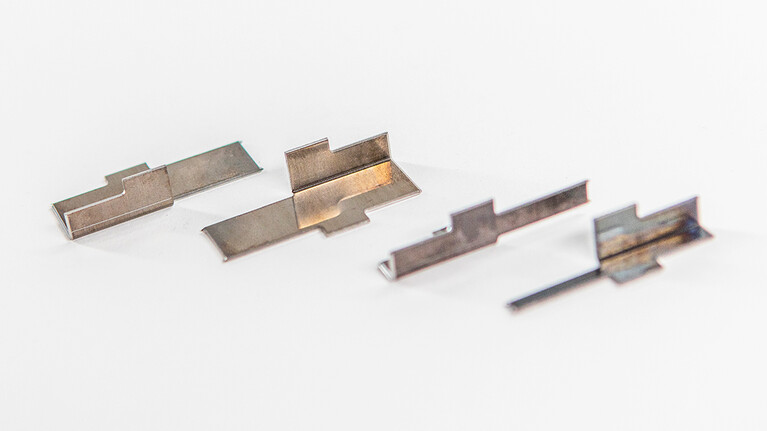

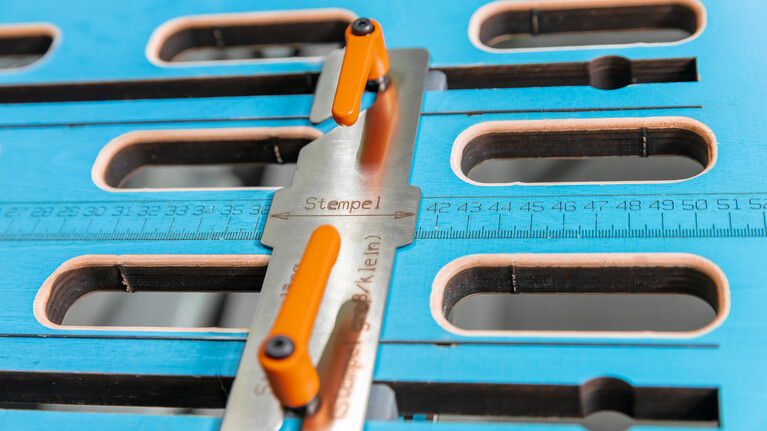

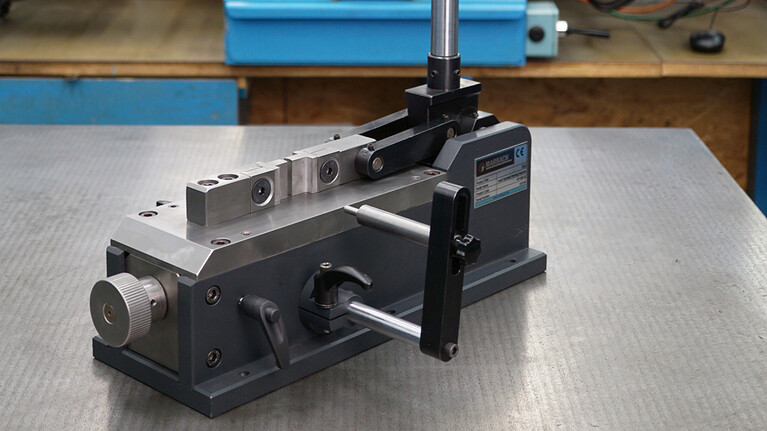

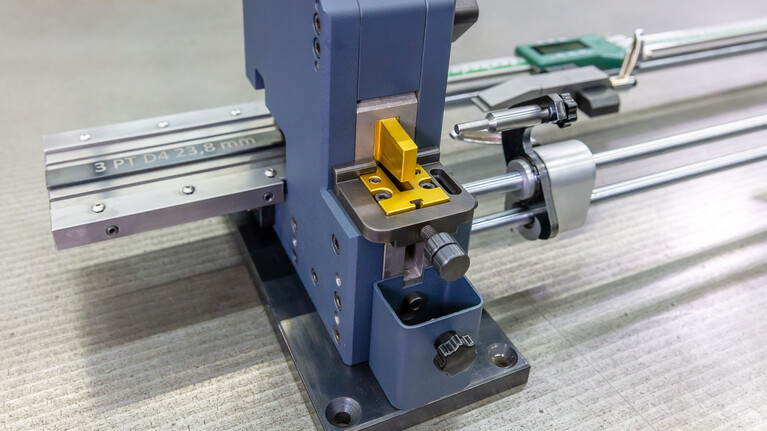

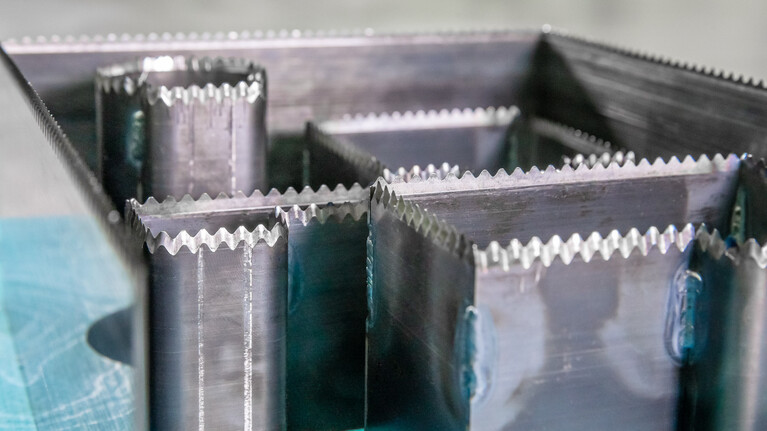

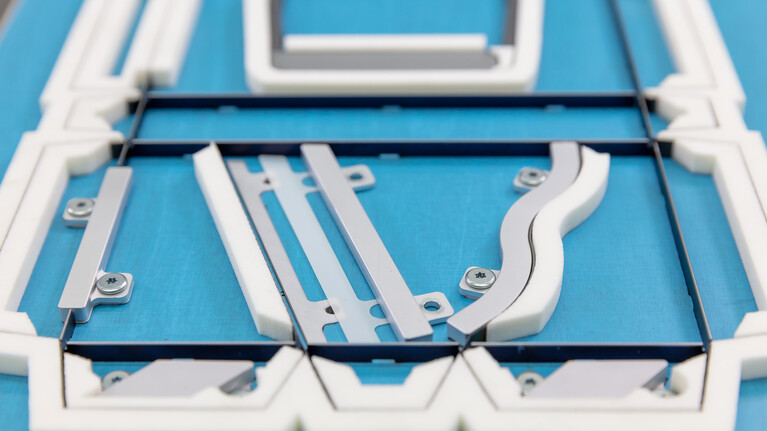

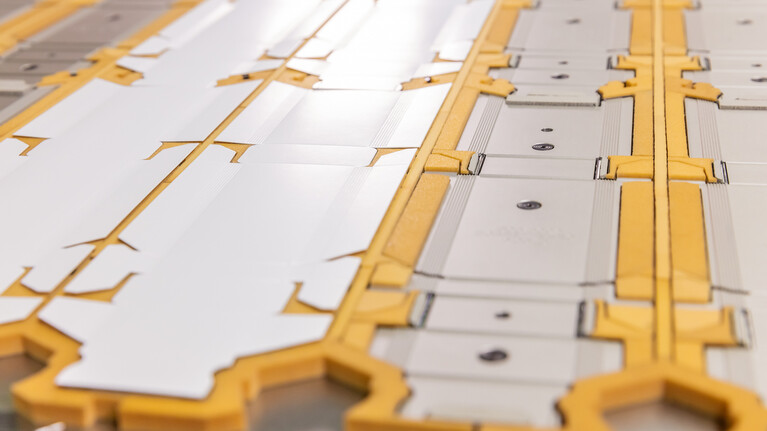

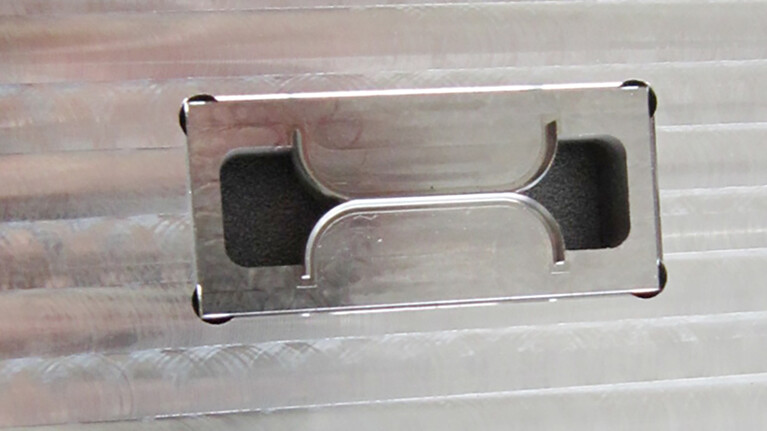

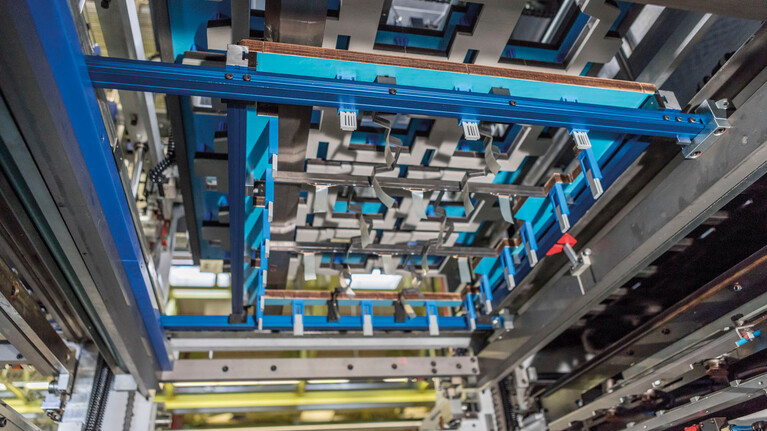

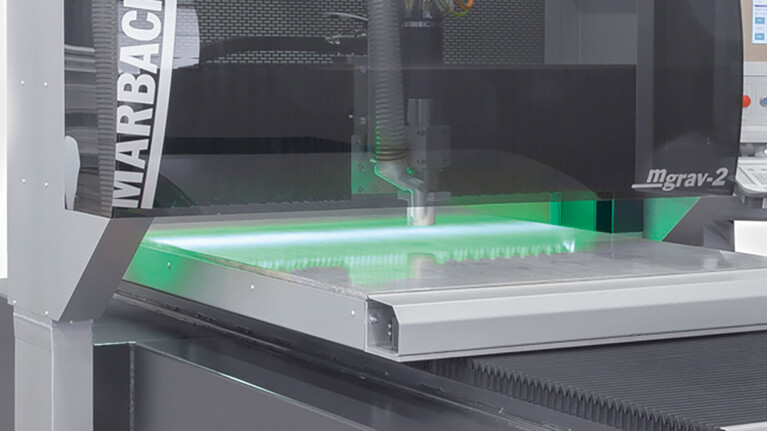

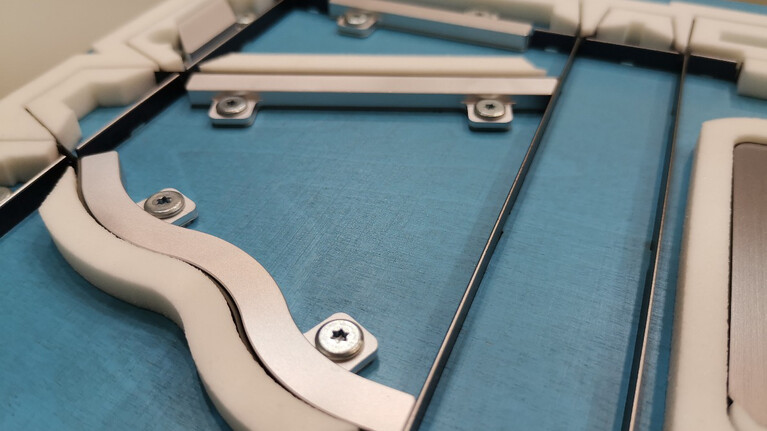

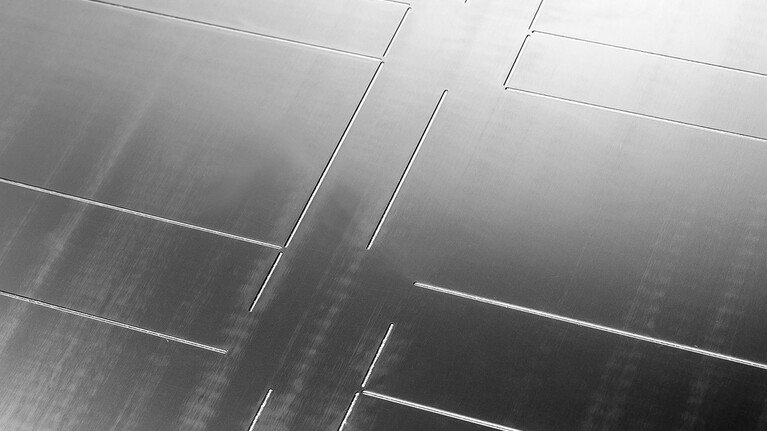

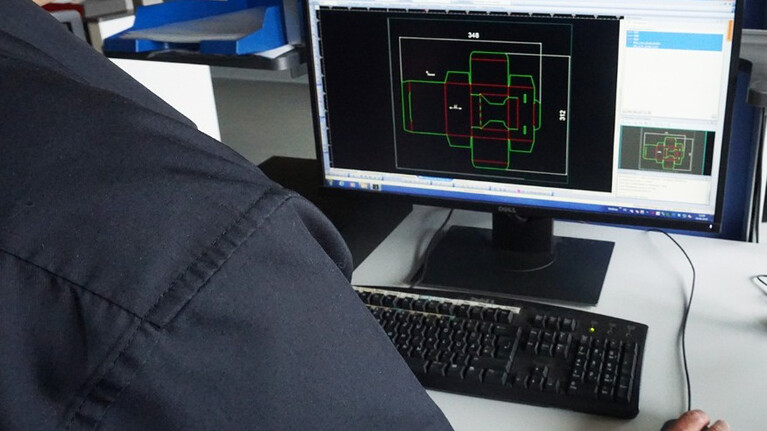

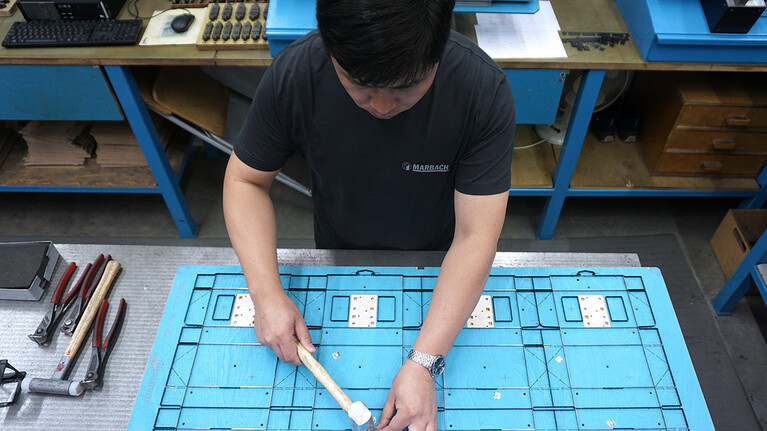

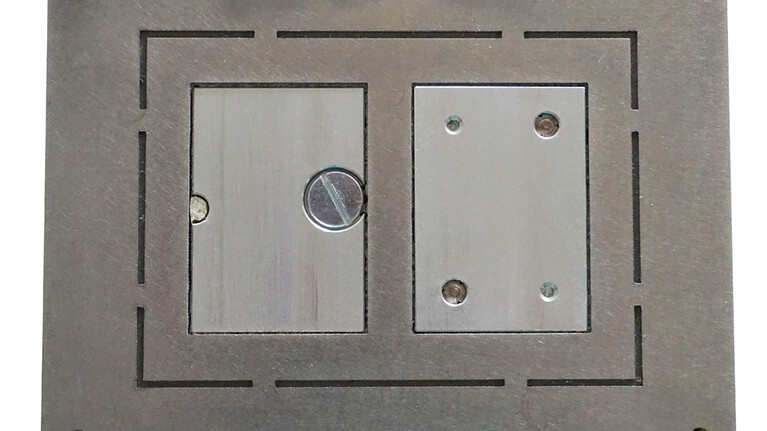

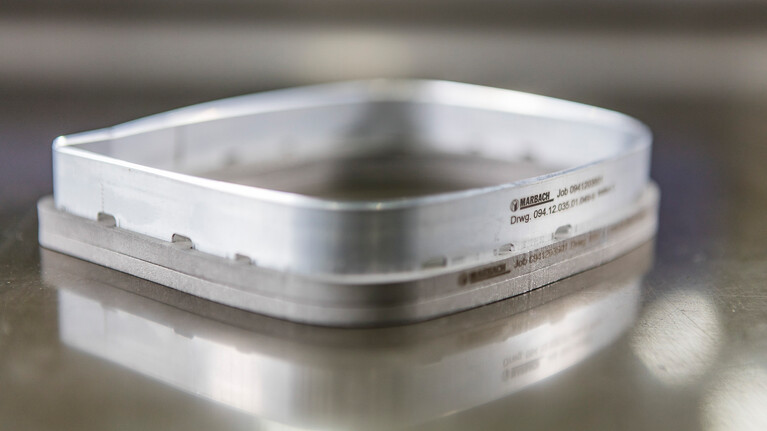

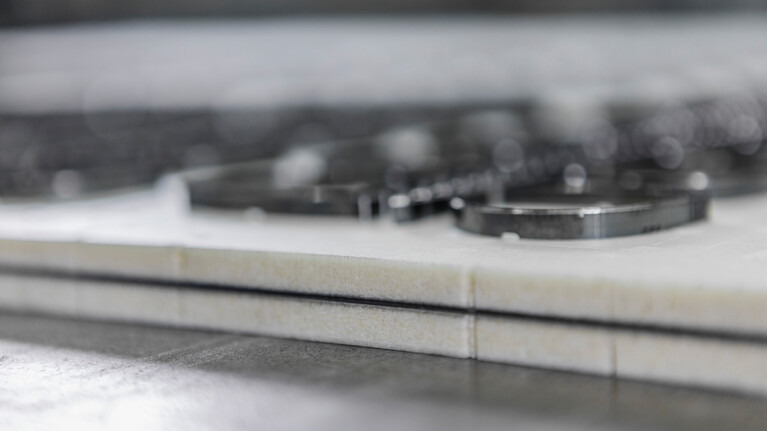

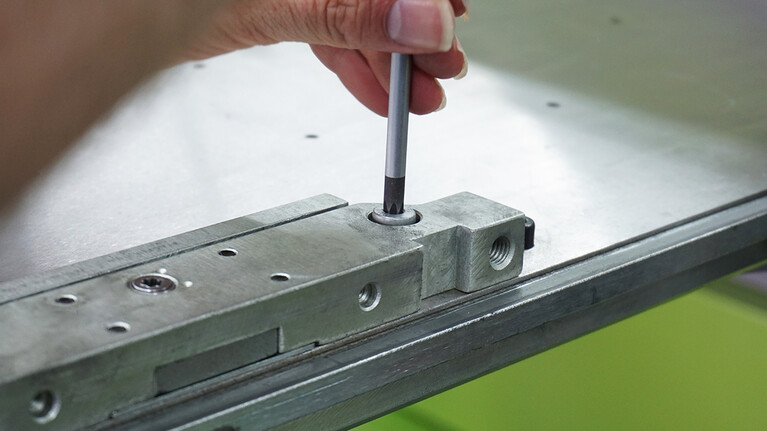

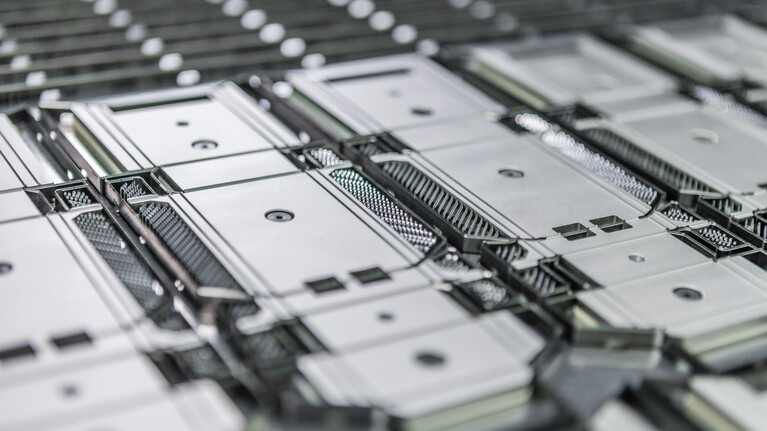

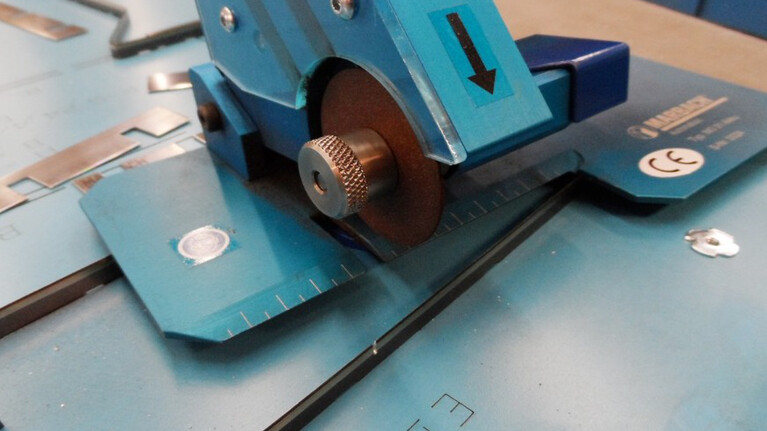

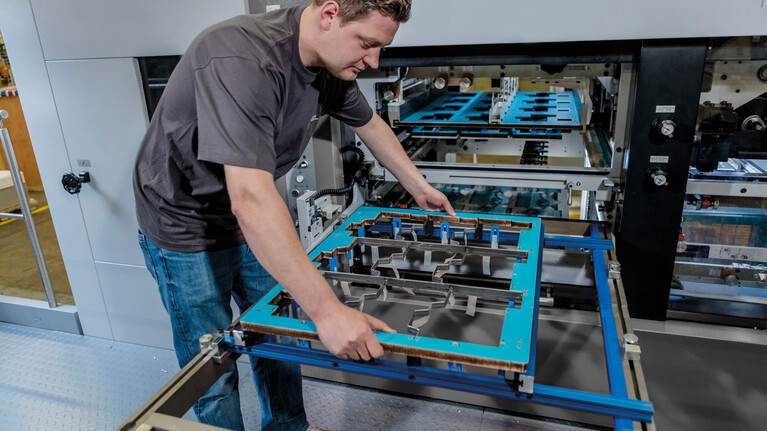

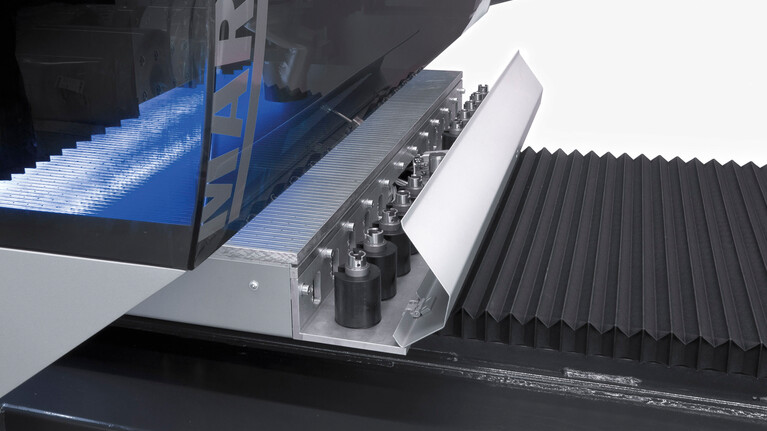

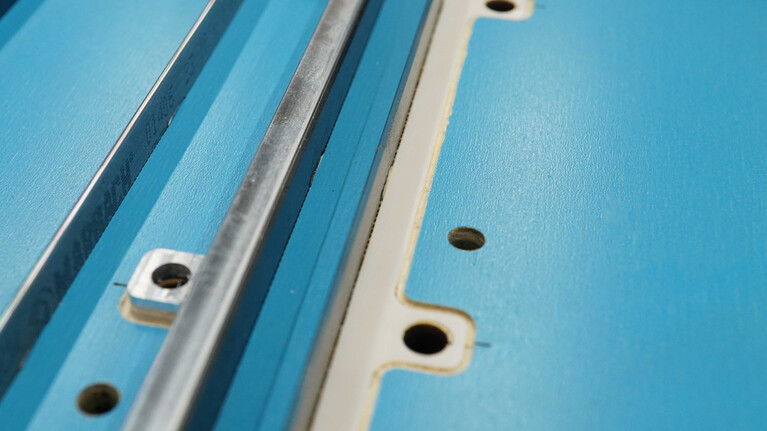

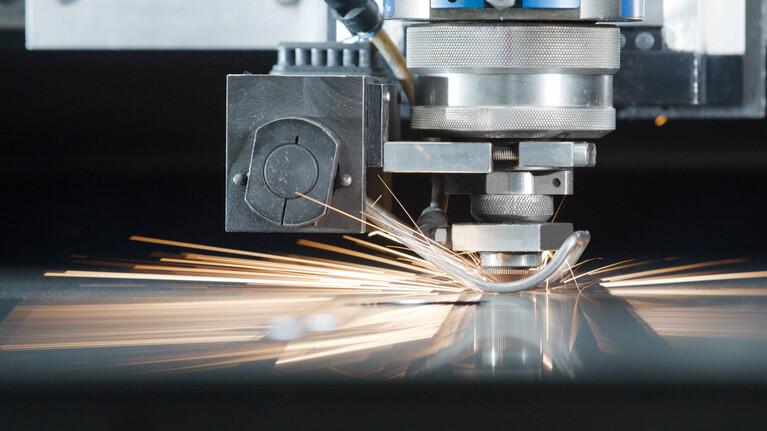

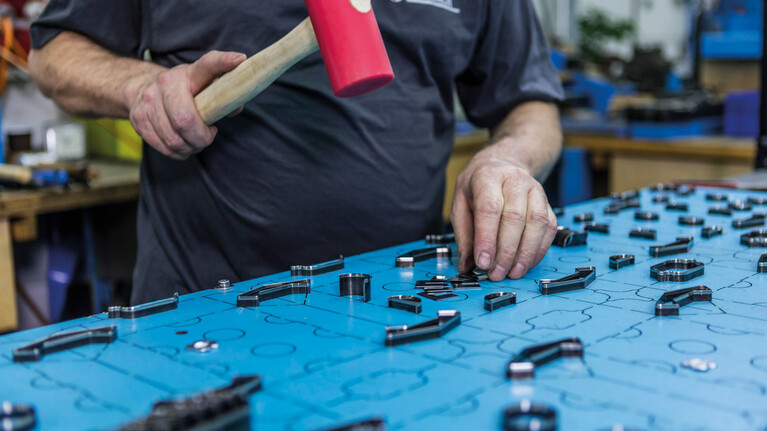

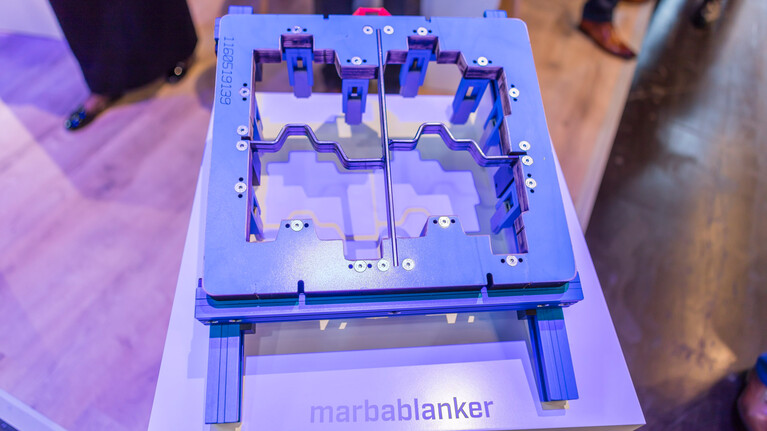

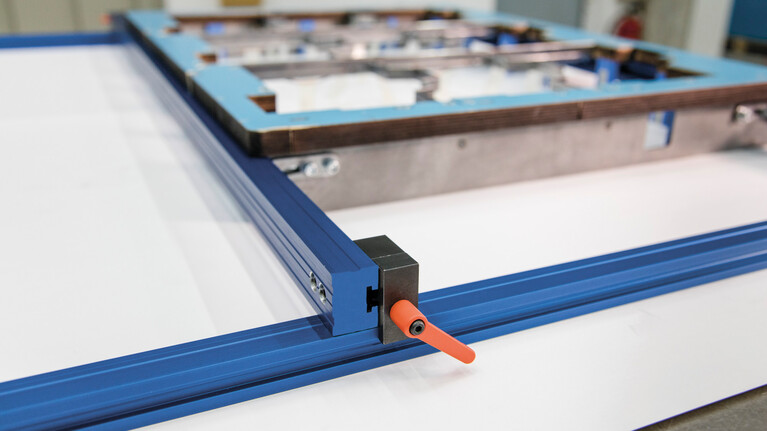

Precisely calibrated die-cutting machine.

With marbazero and the calibration tool from Marbach.

We have a solution in our portfolio that allows the individual workstations as well as the upper and lower tool parts of a die-cutting machine to be perfectly matched to each other. We simply call this solution the "Marbach calibration tool".

die-cutting technology

02. March 2018

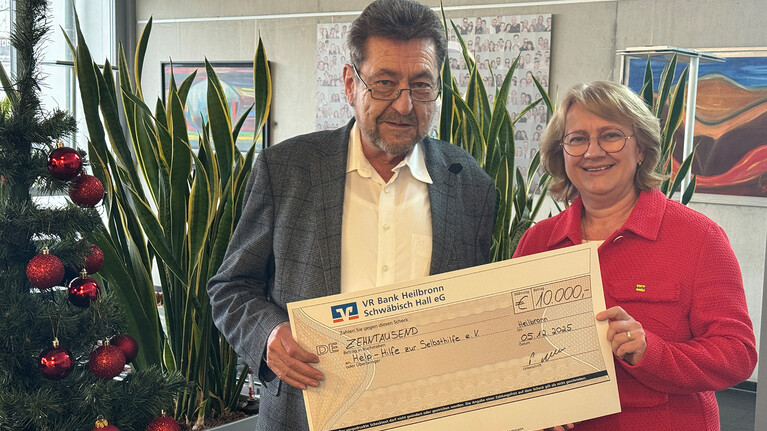

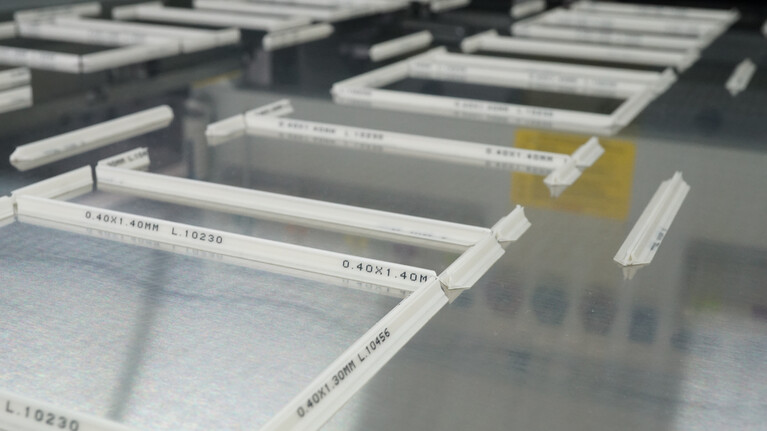

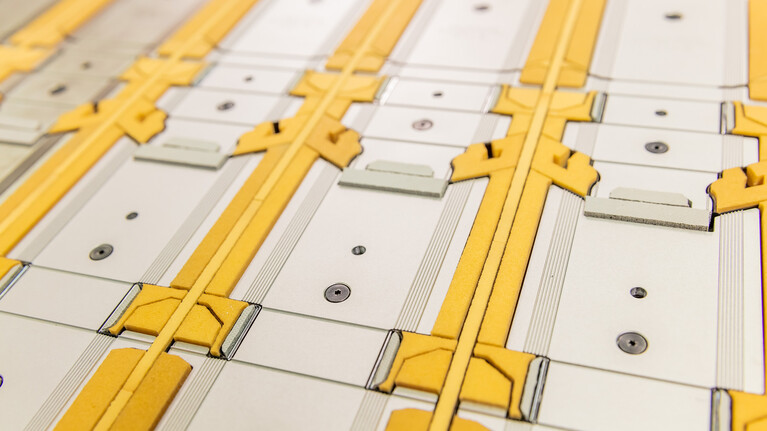

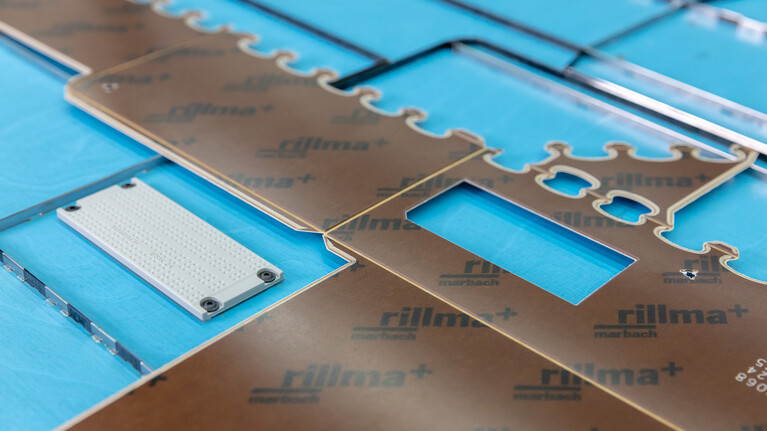

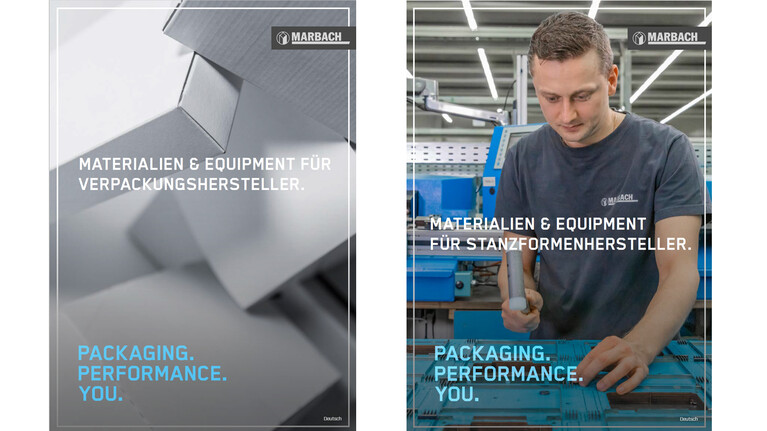

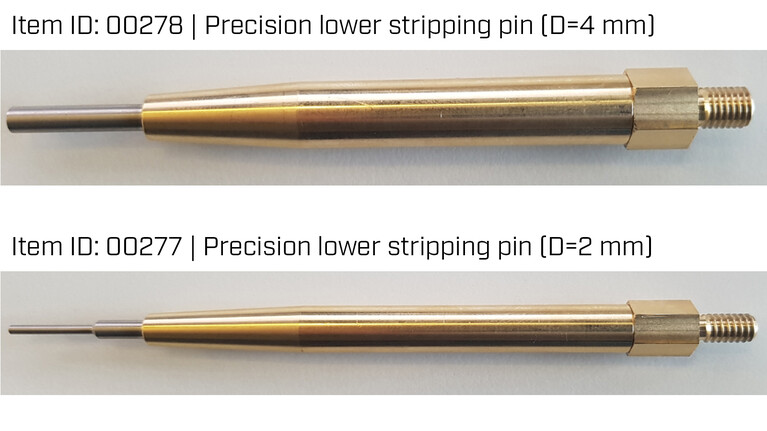

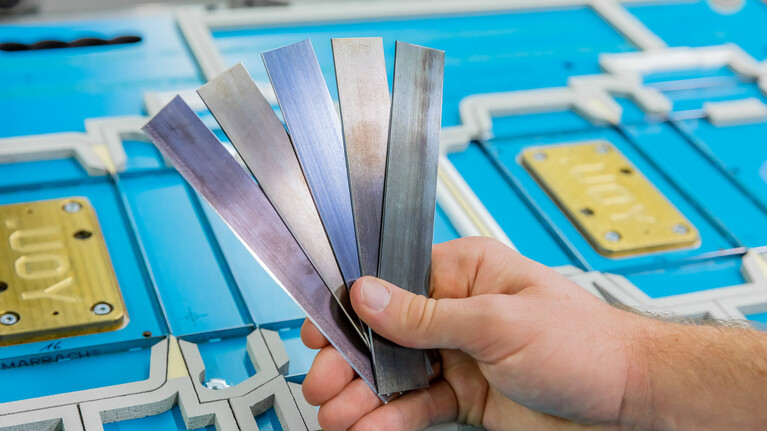

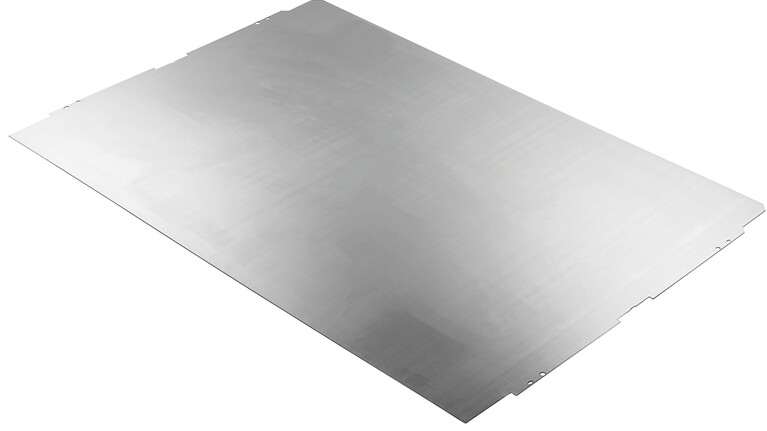

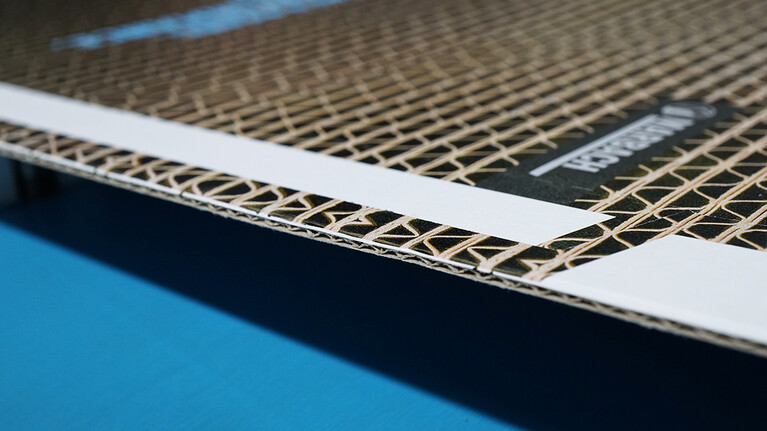

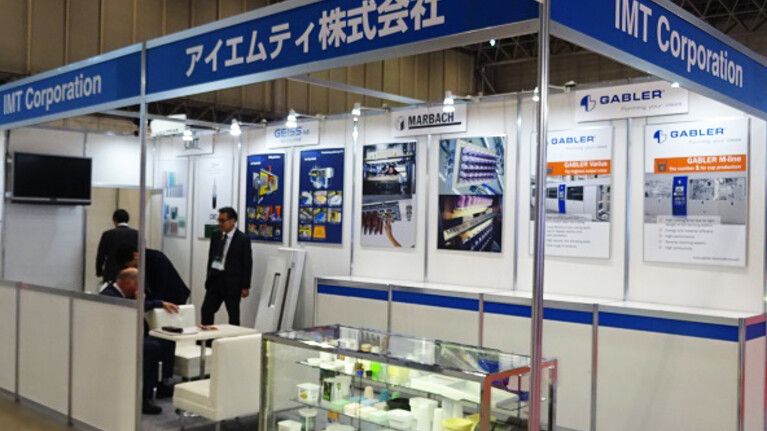

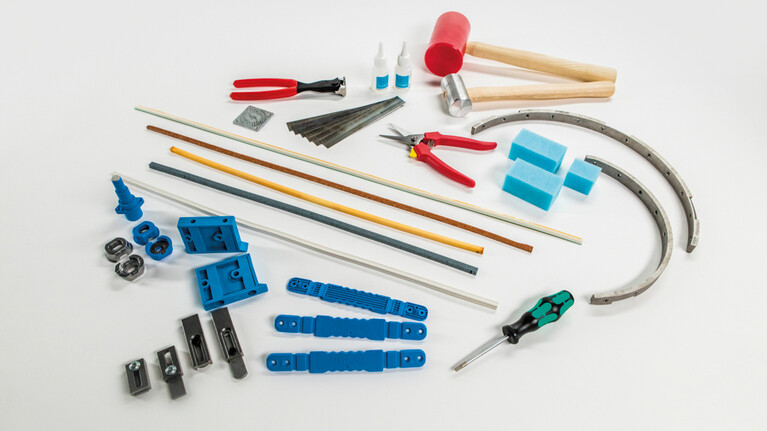

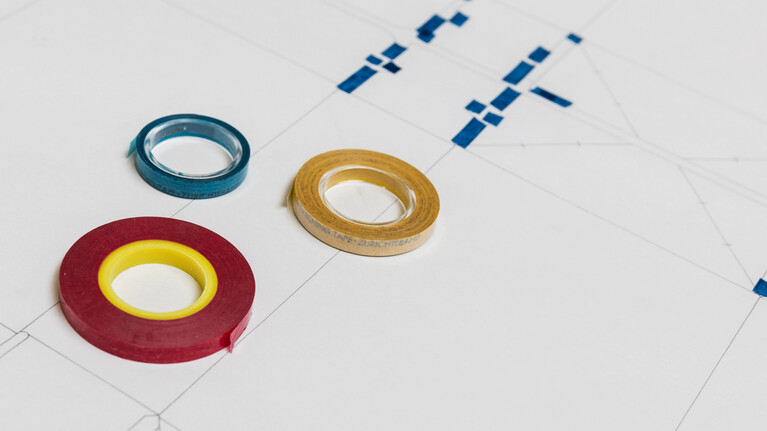

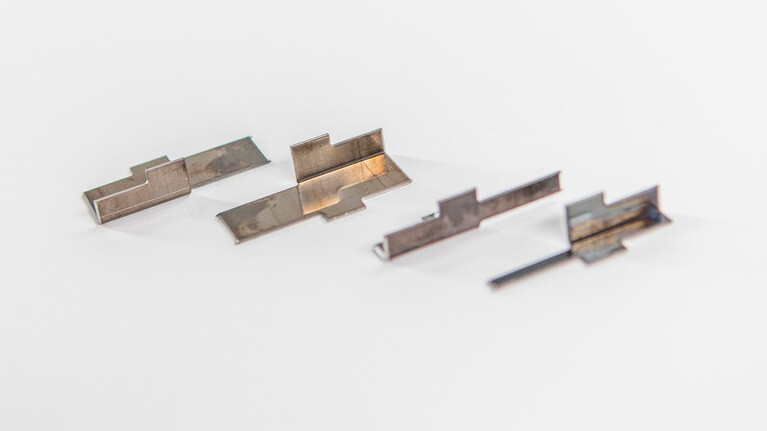

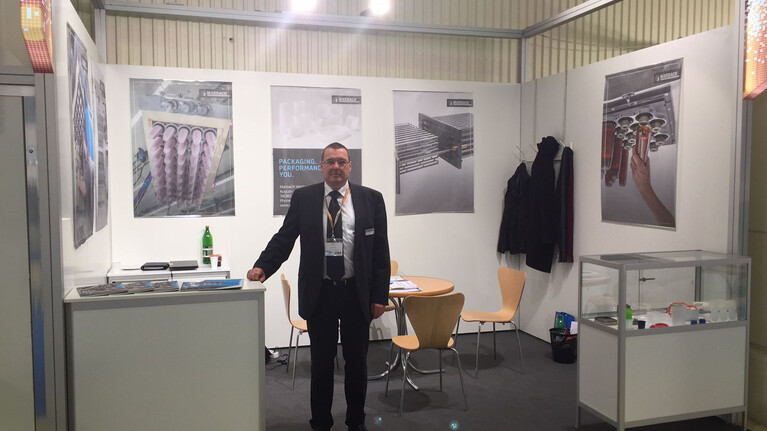

New catalog for materials.

Marbach Die Supplies presents its product portfolio for printing plants.

Marbach Die Supplies, one of the large material retailers in Germany, has recently expanded its product portfolio for materials. In order to provide its customers and interested parties an overview of the wide range of services in the area of materials for packaging manufacturers, Marbach has presented its new product catalog. Interested individuals can request the new Marbach catalog at marketing@marbach.com.

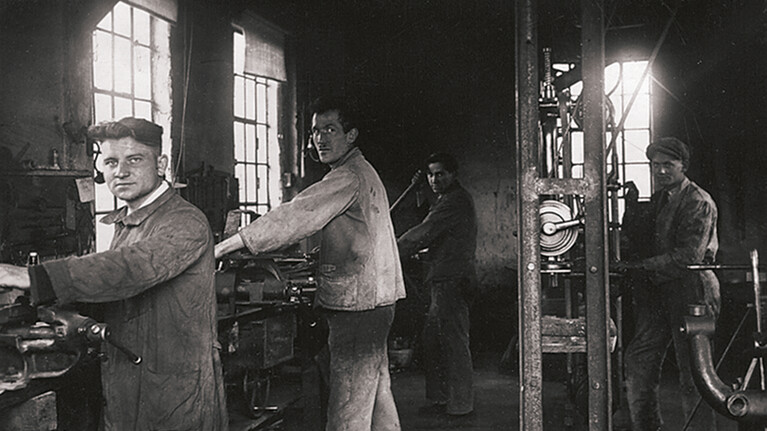

27. February 2018

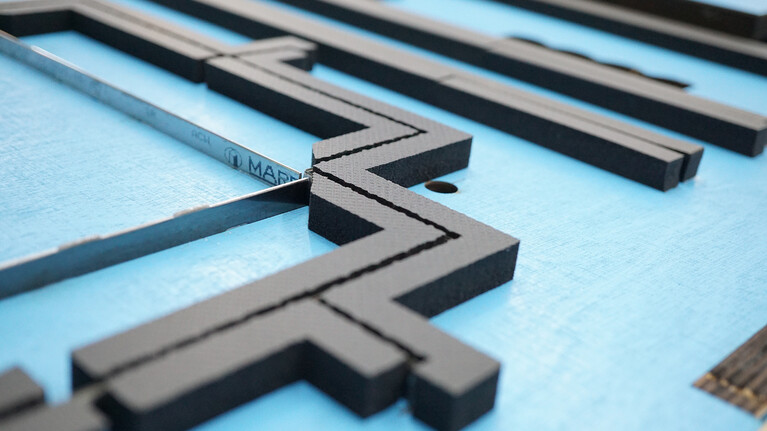

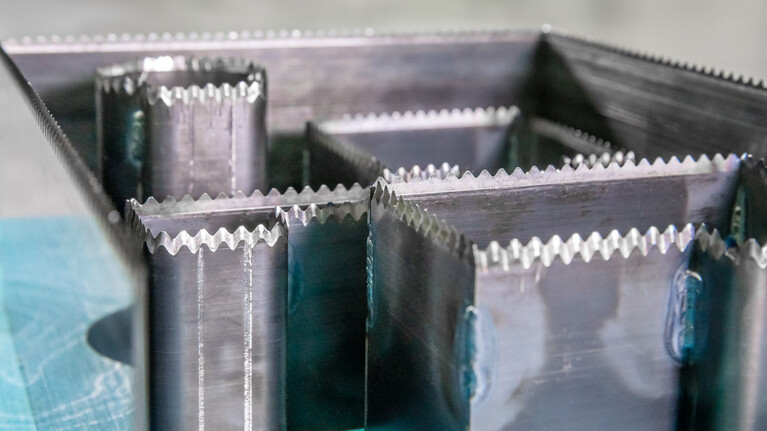

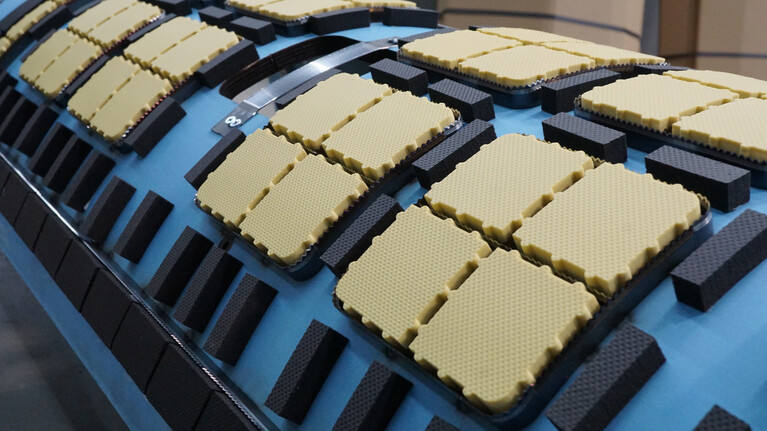

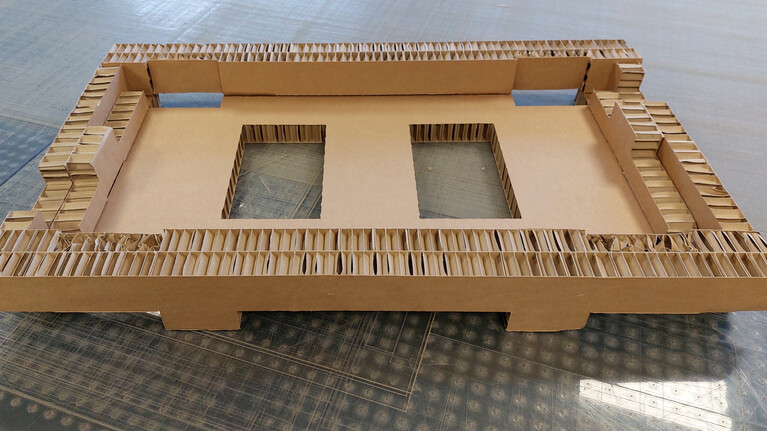

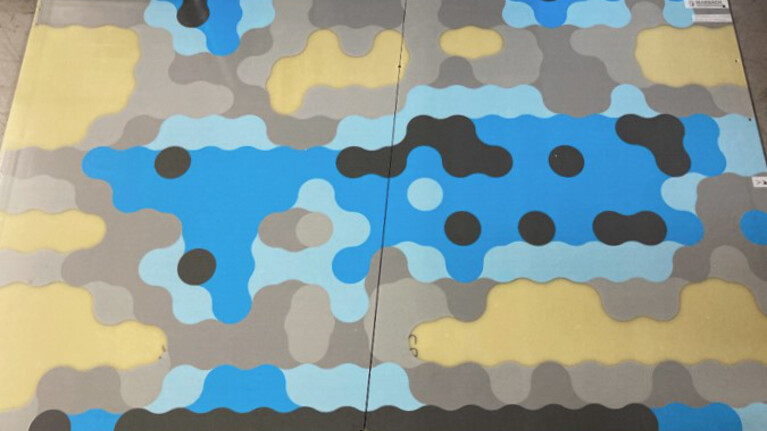

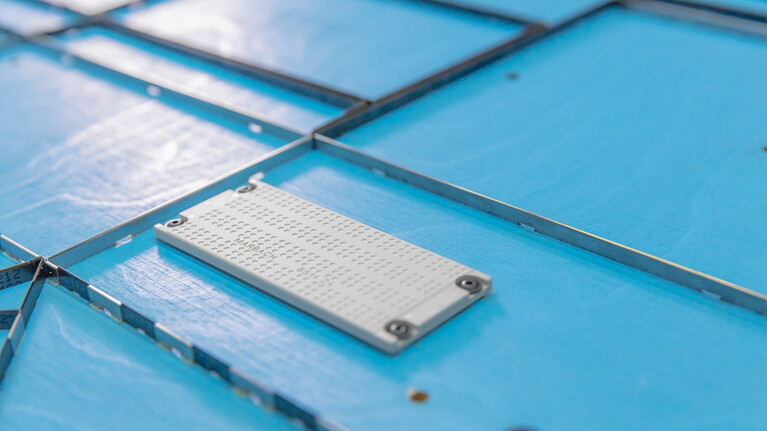

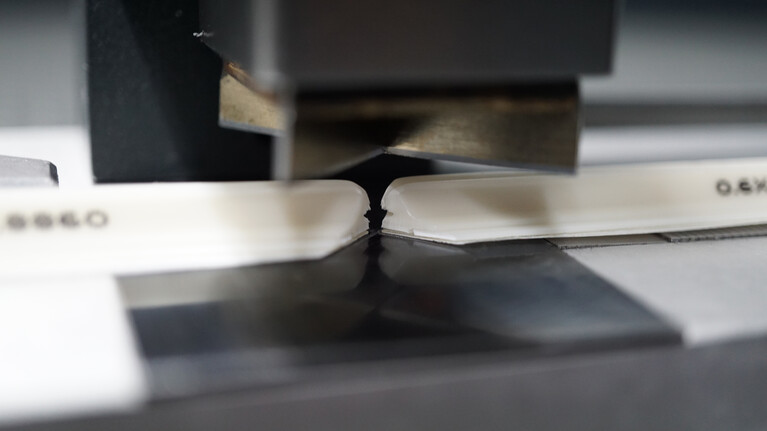

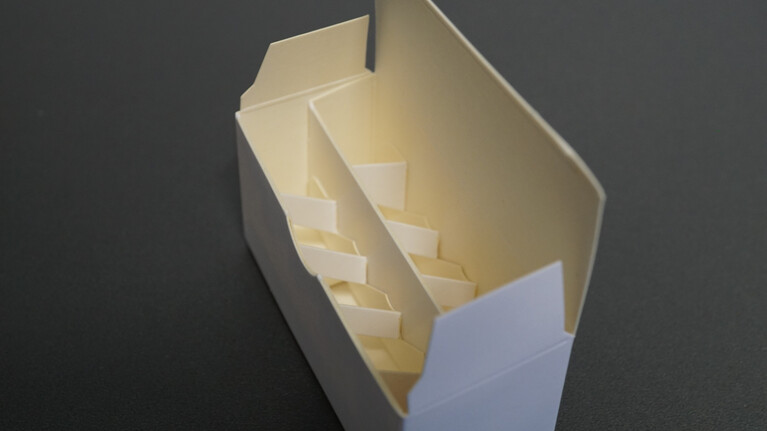

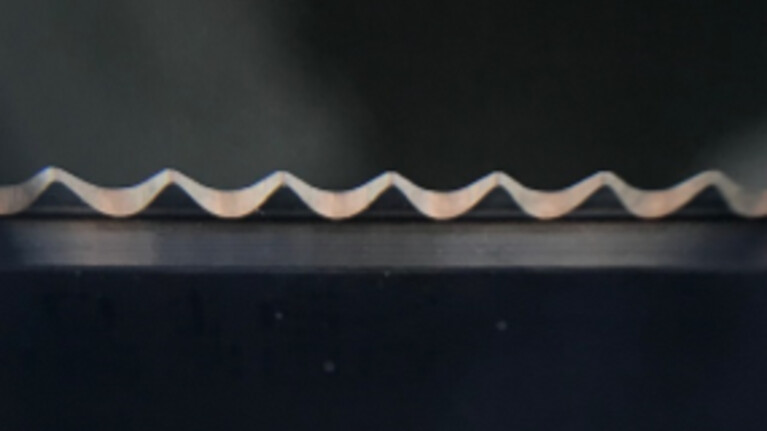

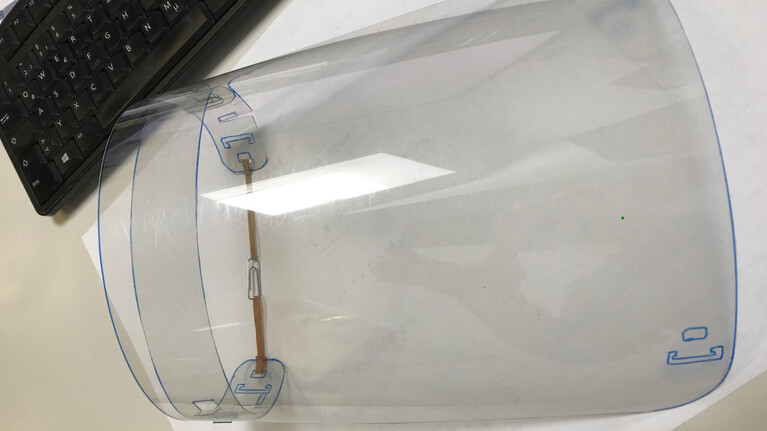

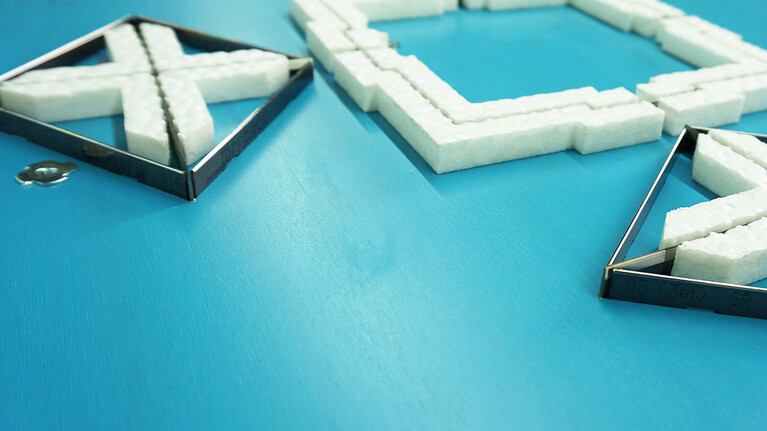

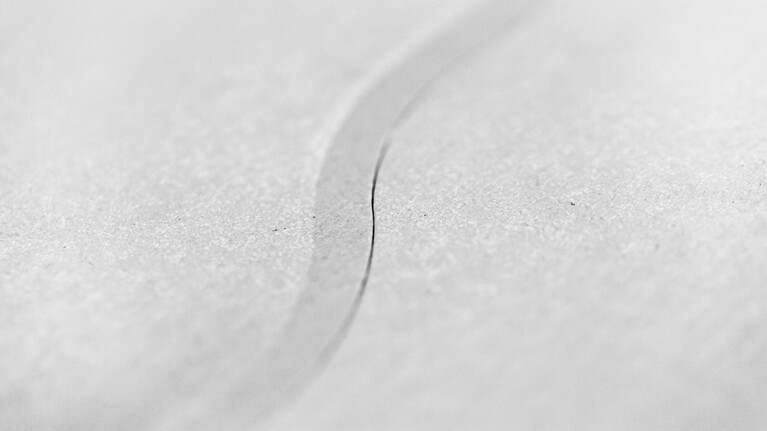

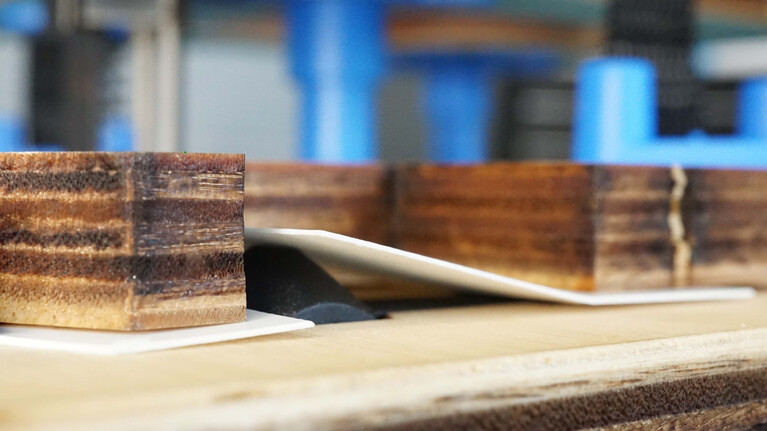

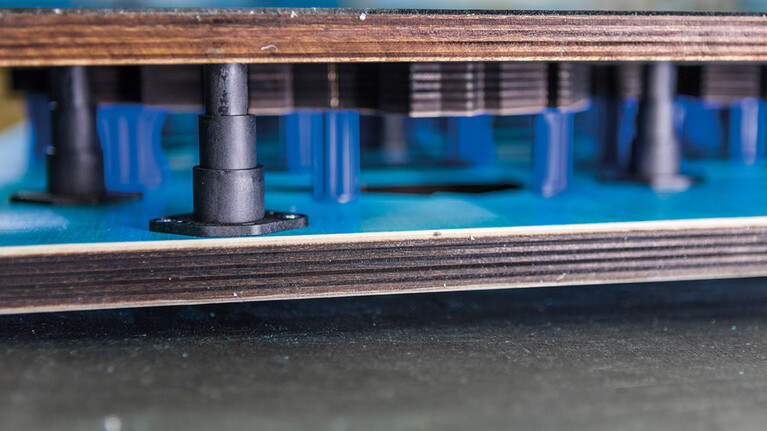

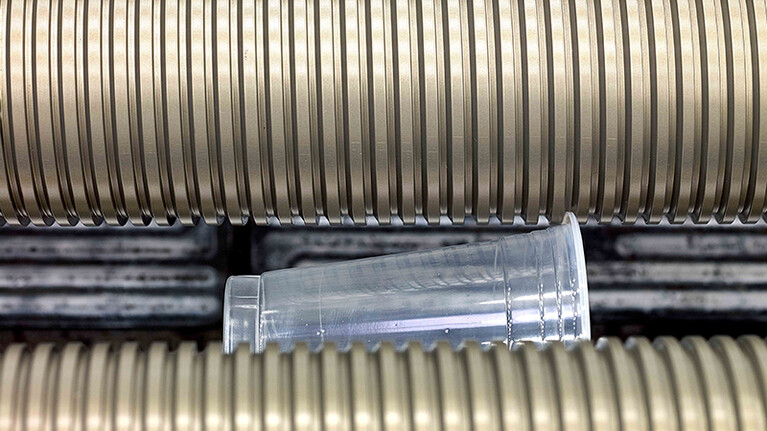

Efficient embossing. Also for small quantities.

Marbach polymar now available.

Marbach is known for its progressive development work. The lastest Marbach innovation: polymar-embossing. Recently announced, it is now available at Marbach for Germany, Austria and Switzerland. Those who want to convince themselves first hand of the quality of our new embossing solution can order sample packaging at Marbach via email: marketing@marbach.com.

22. February 2018

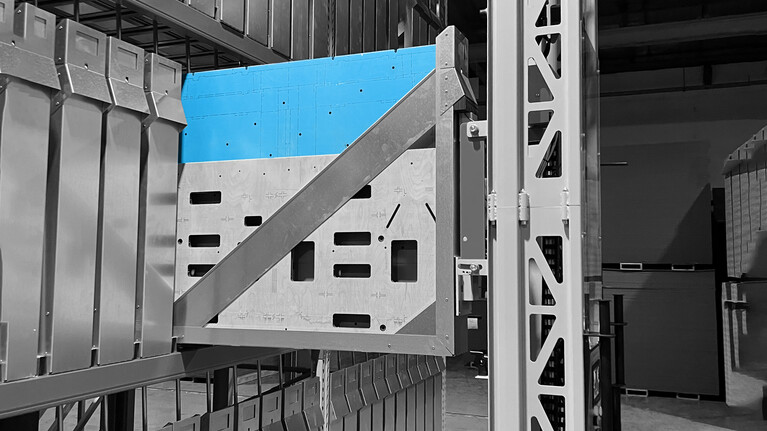

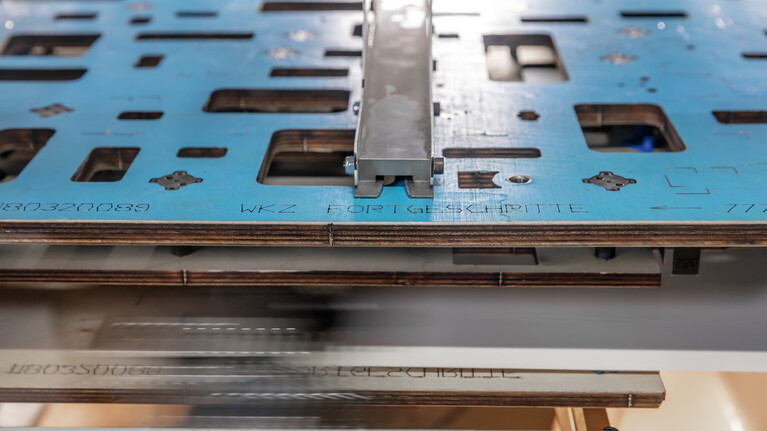

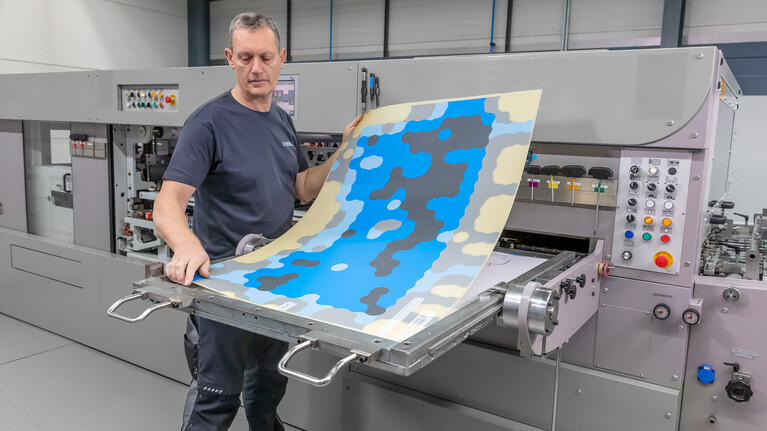

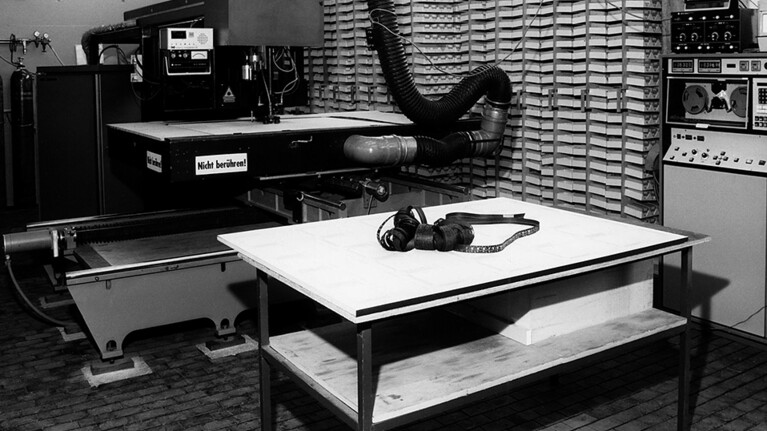

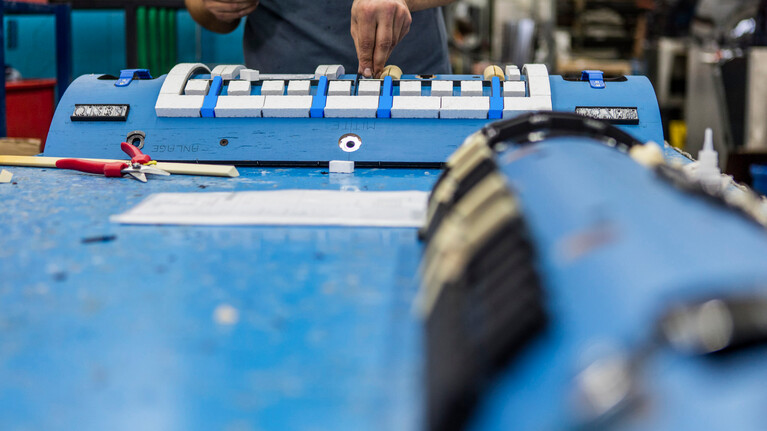

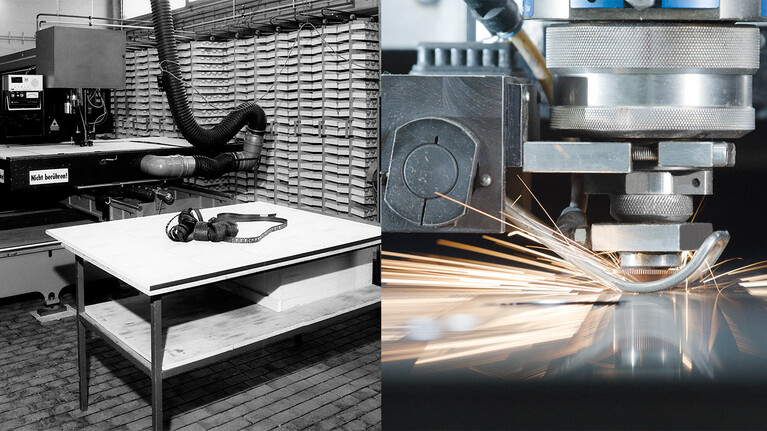

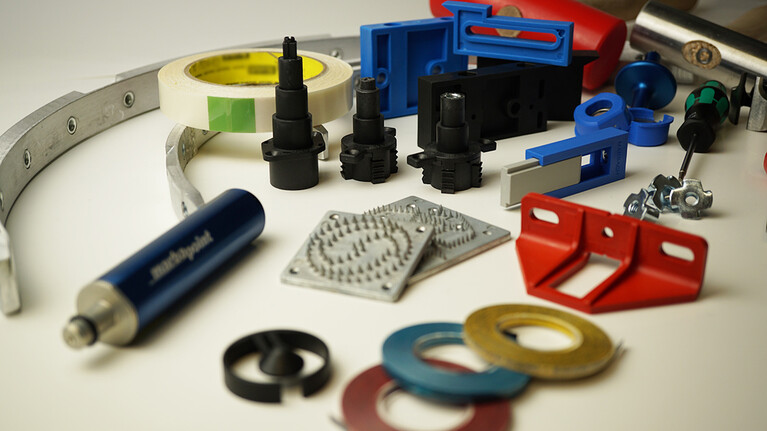

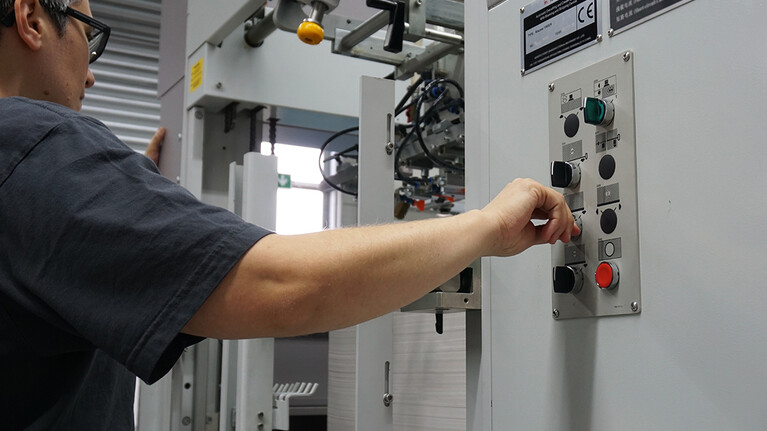

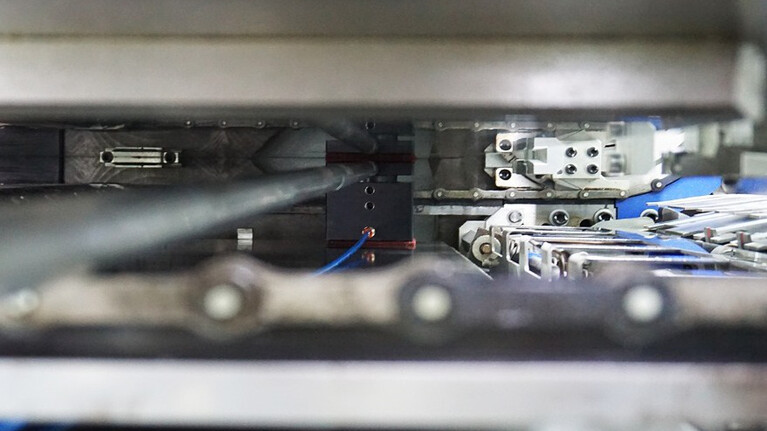

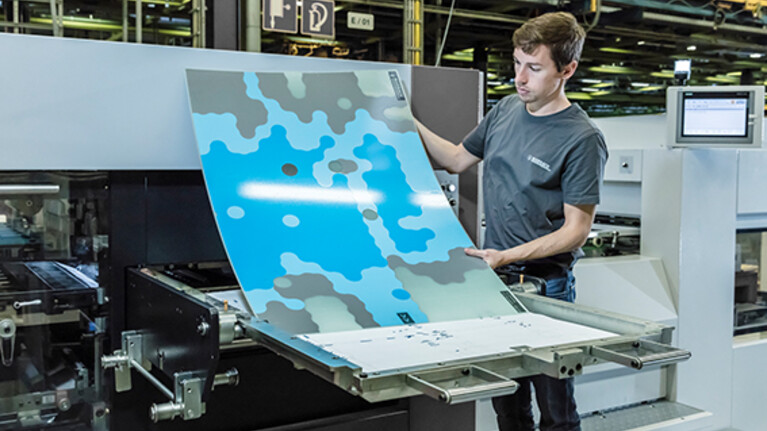

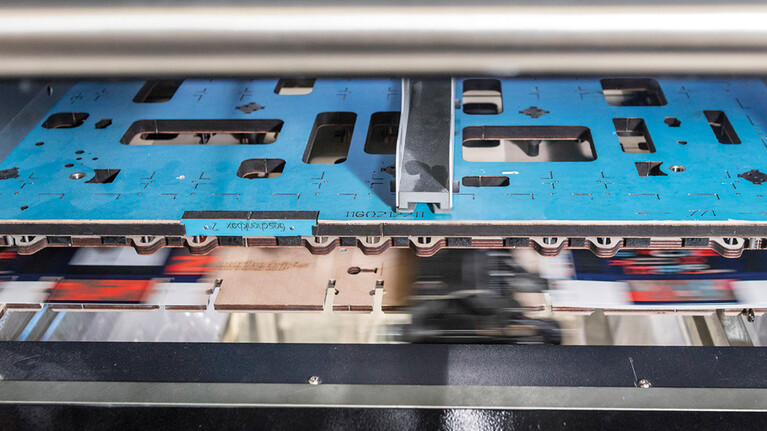

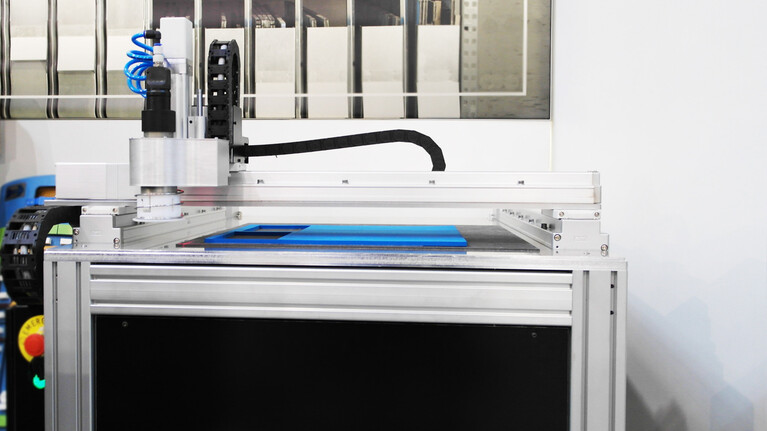

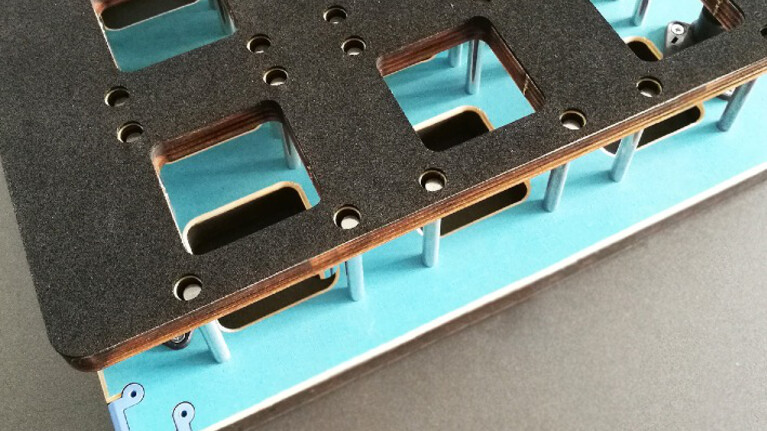

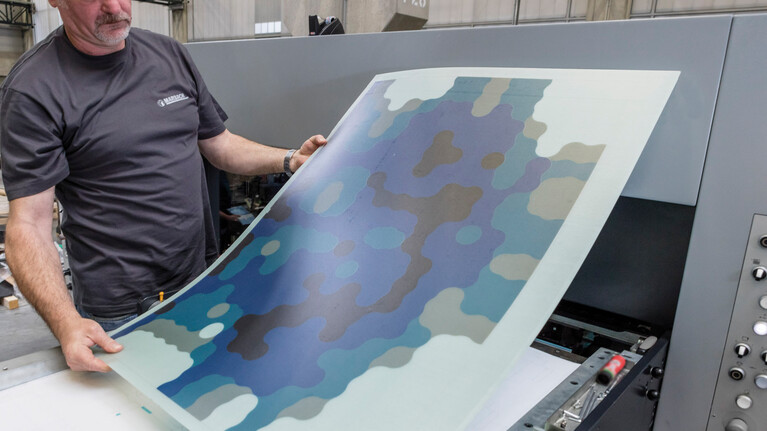

New Marbach Training Center.

Marbach Academy will open soon.

Since July 2017, the inventory of Marbach has included an on-site die-cutting machine from Brausse. After having used the past few months to provide employee training courses, initial customer training classes and to conduct product tests, the Marbach Academy will soon be officially opened. If you are interested in a training course, you can request a training brochure at academy@marbach.com. Alternatively, all information about the Marbach training courses can also be found on the company's homepage www.marbach.com/trainings.