die-cutting technology

9. October 2020

Highest efficiency in the tobacco packaging process. Marbach extends existing technology.

Marbach, global acting diemaker, has further developed its crease plate technology which has already proven its worth over years. With the new crease-plate-die|+ and the crease-plate-die|rc Marbach provides tool solutions for the cigarette industry with even higher performance potential.

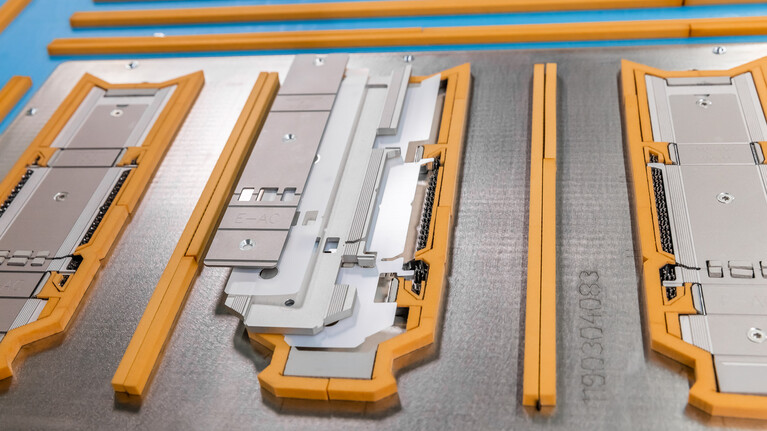

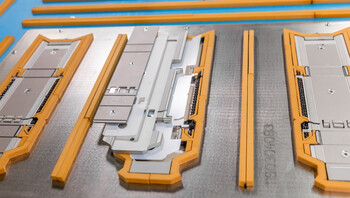

crease-plate-die|+

The crease-plate-die|+ is a further development of the existing Marbach crease-plate-die technology. The difference: the new crease-plate-die|+ creases with a defined end gauge. This allows an even more precise make-ready and a more consistent crease shape. Ensuring the best quality of packaging blanks and high packaging speeds.

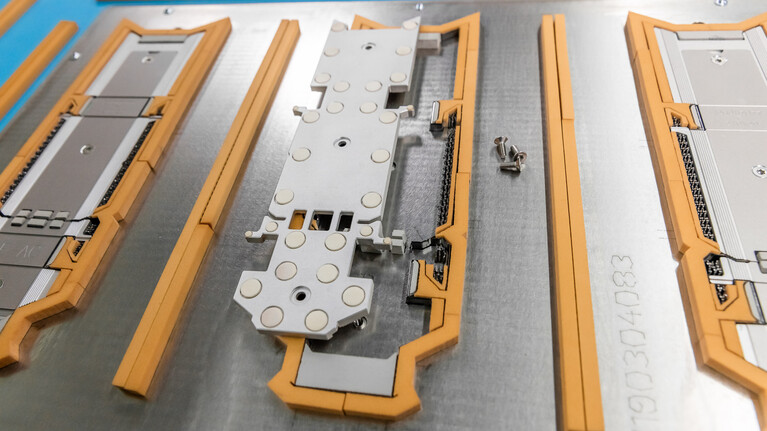

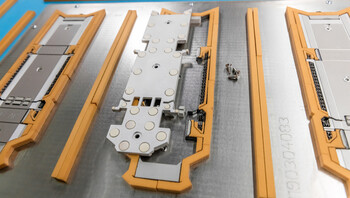

crease-plate-die|rc

The crease-plate-die|rc is a special solution for cigarette packaging in round corner design. It includes the same technology as the crease-plate-die|+, but is supplemented.

Bernhard Reisser, International Sales Manager at Marbach: "The special effect of round corner packaging is created because several creases are arranged very closely next to each other on the blank. This looks great in the final packaging but creates very special challenges for the tool. Especially since the paperboard materials used in the tobacco sector are becoming more and more diverse. With round corner creases, the forces that impact the paperboard are significantly different from those with standard creases. If the creases cannot be individually set-up, it is almost impossible with some paperboard materials to achieve high-quality blanks with the creasing specifications defined by the end customer."

Thanks to the new Marbach crease-plate-die|rc, the make-ready of the normal cross creases of a crease-plate-die can be isolated from the round corner creases. This allows the cutting-die make-ready and the adjustment to the creasing parameters specified by the cigarette manufacturer to be carried out quickly and easily, even with changing board materials of the same thickness and grammage as well as fluctuations in board quality. All of this ensures high-quality round corner blanks that meet the cigarette manufacturers' high demands on packaging quality and speed.

With the new Marbach solutions, packaging manufacturers and brand owners benefit from best performance.