Marbach. Packaging. Performance. You.

Be inspired. By stories about the packaging industry. About Marbach. And about what Marbach can make possible for you.

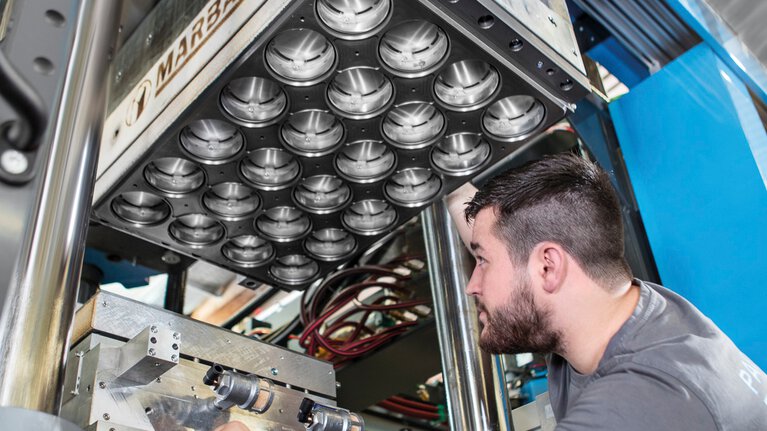

Be excited. By the best performance. Of products made for you. Individually. With passion. With experience. Each one custom made. Be delighted. About everything we can achieve for you. With cutting dies. With rotary tools. With thermoforming tools. Machines. And materials.