die-cutting technology

6. November 2025

A tool that delivers what it promises. CPS & CPS-R – high-performance systems for maximum performance in corrugated board processing.

We have developed two system solutions: the Corrugated Performance System (CPS) for flat dies and the CPS-R for rotary dies. These solutions impress packaging manufacturers with maximum productivity, maximum dimensional accuracy, and waste-free results. Both systems stand for stable processes, minimal set-up times, and a significantly extended tool life, regardless of machine type or manufacturer.

Packaging manufacturers are under high pressure every day: machines must run reliably, packaging must be precise and functional, and waste must be avoided. This is exactly where CPS and CPS-R come in. Both systems are based on a standardized design and perfectly matched components that ensure stable and economical processes in any production environment.

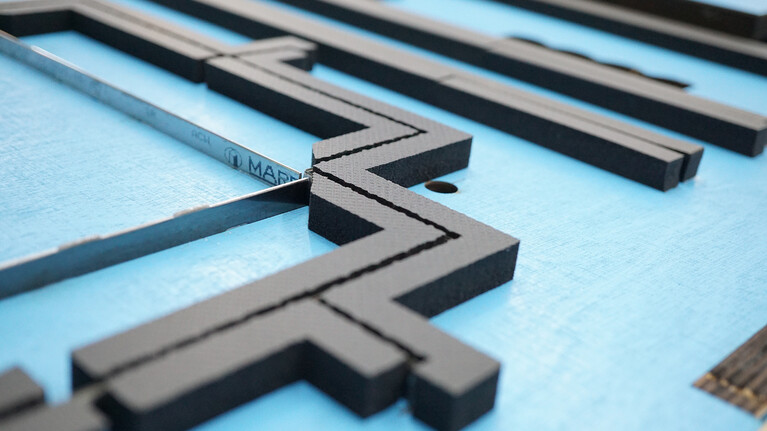

CPS – The high-performance system for flat corrugated board dies.

With the CPS – Corrugated Performance System, we offer a “ready to run” solution for flatbed die-cutting of corrugated board. The system significantly reduces set-up times and ensures a stable production process without sheet breaks and little to no regrinding of nicks. The precise coordination of all components – from the cutting rules to the supports to the ejection elements – achieves 100% waste-free results. At the same time, the cutting quality remains consistently high over a long service life.

Another advantage is the lower cutting pressure: through the targeted interaction of the materials, this can be reduced by up to 10%, which protects the machine and material. Each tool is individually matched to the paper quality, ensuring an optimal start to production.

“The special feature of the CPS is its intelligent system coordination. It ensures stable processes, reduced set-up times, and consistently precise results with minimal wear.” says Patrik Wappler, Performance Manager at Marbach.

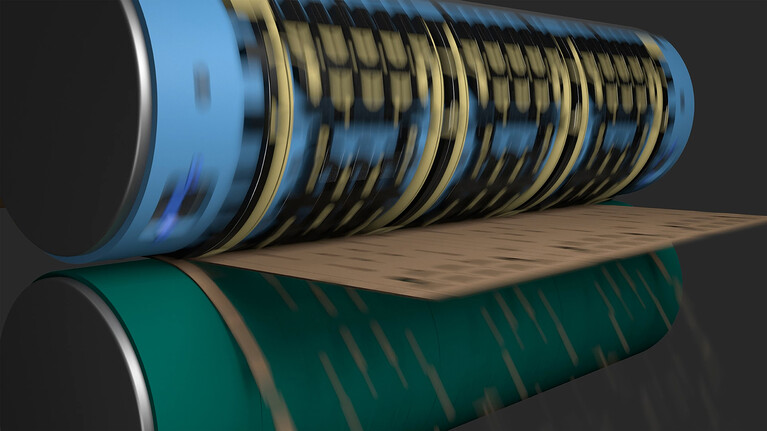

CPS-R – The high-performance system for rotary corrugated board tools.

The CPS-R – Corrugated Performance System-Rotary is the rotary version of the system. It offers packaging manufacturers a uniform quality standard for all machine types and locations. Thanks to state-of-the-art laser technology, high-quality materials, and assembly-optimized design, the system works precisely and economically right from the start. Waste-free processing, high dimensional accuracy, and short set-up times result in maximum machine uptime and stable production conditions.

In addition, low-wear materials significantly extend tool life and reduce maintenance costs. Users benefit from consistently high die-cutting quality, lower production costs, and smooth processes.

"With the CPS-R, we are setting new standards in rotary corrugated board processing. Precision, cost-effectiveness, and durability are combined in a system that brings noticeable benefits in everyday use." emphasizes Ingo Graham, Product Manager at Marbach.

Whether flat or rotary, with CPS and CPS-R, we offer a consistent tool concept that ensures maximum efficiency, process reliability, and quality in corrugated board processing. Both systems stand for performance, stability, and cost-effectiveness, and thus for tools that deliver what they promise.