die-cutting technology

28. January 2026

Optimal die-cutting results for corrugated board. marbacover|2.0 reliably reduces bursting of inner layers.

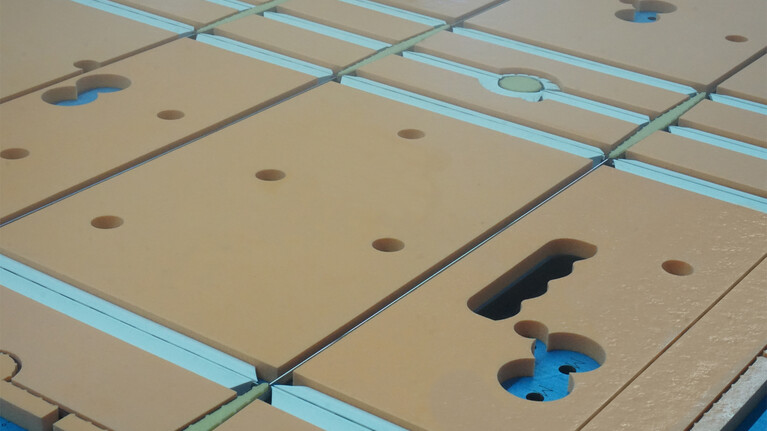

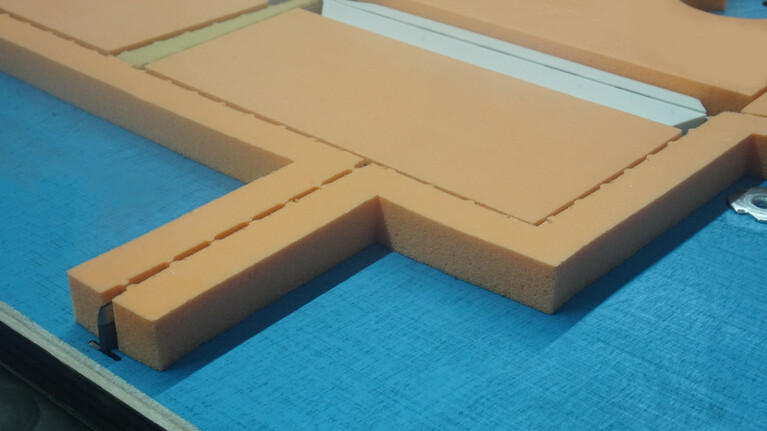

We have developed marbacover|2.0, a special tool technology that makes die-cutting corrugated board packaging significantly more reliable. The tool minimizes the bursting of inner layers and enables consistent, high-quality die-cutting results, even with demanding corrugated board qualities.

Die-cutting corrugated board creates material-related stresses which, depending on moisture, structure, and raw material quality, can lead to ceiling cracks. This problem occurs particularly with corrugated board with a high recycled content, which is increasingly being used in sustainable packaging solutions. For packaging manufacturers, this often means a loss of quality and limited production reliability.

"The special feature of marbacover|2.0 is the full-surface covering with a specially matched rubber material. This ensures that the corrugated board is compressed evenly during the die-cutting process, tensions are specifically reduced, and the material structure remains stable," explains Ralf Nuyken, Industry Manager at Marbach.

marbacover|2.0 is suitable for almost all common corrugated board qualities, offering an economical and flexible solution for a variety of production requirements.