Thermoformed trays.

Multi-chamber trays with perforation.

Multi-chamber trays with perforation are plastic packaging that are mainly used in the food sector and for pet food.

The original function of the multi-compartment package is portioning. In the case of packages without perforation, the products are separated within compartments by webs. This is particularly useful for TV dinners, etc. If a perforation is made, several portions can be made from one complete unit, which can then be separated individually. On the one hand, this is practical to take with you on the go, and on the other hand, the other portion remains in its original packaging and thus has a longer shelf life. For this reason, the pet food industry is one of the largest consumers of such trays.

In the case of dairy products in particular, the two-compartment cup is also used for the separate filling of 2 types of product, which may only be combined immediately before consumption. Yogurt with muesli, candy flakes or a fruit sauce are common options. In the area of ready meals, variations can also be optimally combined with soups and noodles. Depending on the application, it is essential that the articles can be securely separated at the perforation or that they can be folded down precisely.

With Marbach thermoforming tools, you can shape & punch high quality multi-chamber products with excellent efficiency.

Product attributes Multi-chamber trays with perforation.

Here you will find the matching technologies for the production of Multi-chamber trays with perforation.

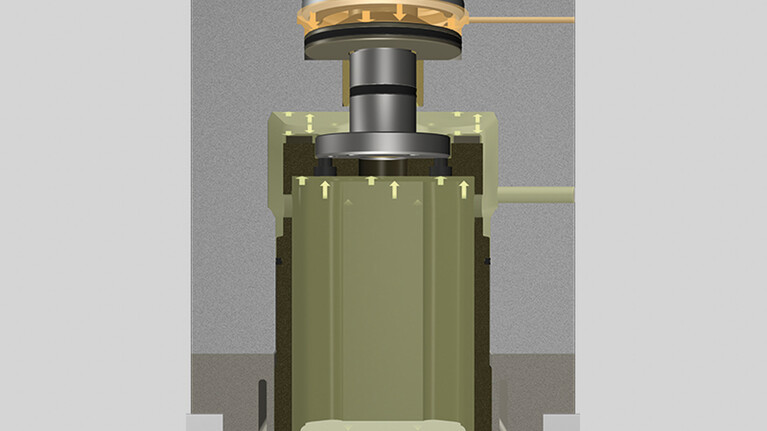

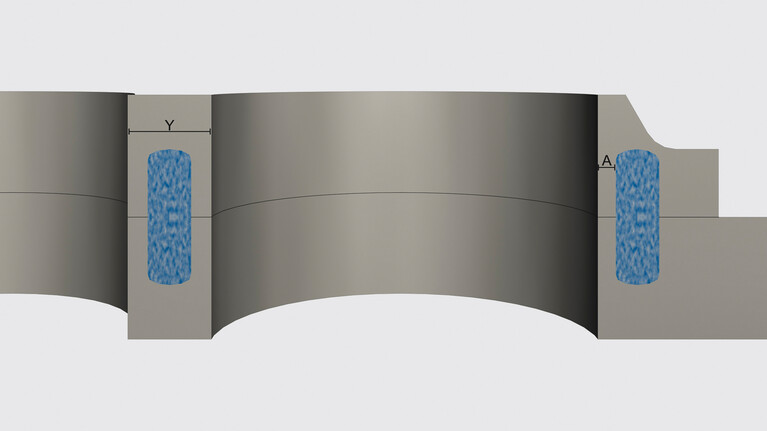

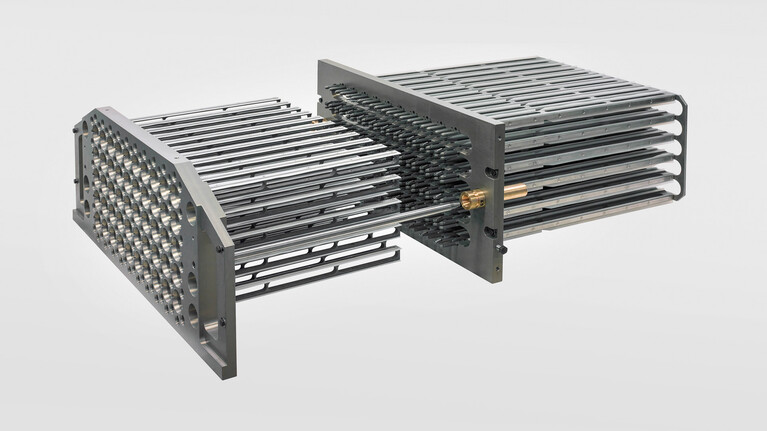

Our tilting tools offer you the best prerequisites for your thermoforming process of multi-chamber trays with perforation. MT|easy speed ensures high production speeds. Our sandwich technology stands for highly efficient cutting plates and the best cooling. The processing of powder metallurgical steel (PM) ensures a long service life, maximum performance, dimensional stability, dynamics and hardness. The 6-pillar guide allows the tightest tolerances to be used.

However, plug assist also has a significant influence on the thermoforming process. We have the right plug assist for your requirements. Mafox|P ensures that the plug can be changed quickly. The Mafox|2 quick-change system allows you to change the ejector bottom in seconds and with Mafox|F, clamp ring crowns can be optimally matched to the product to be manufactured. You control the pressure of the clamp force thorough the pressure-independent clamp rings in the thermoforming process. With our stacking systems, the formed multi-chamber trays with perforation can be reliably stacked in logs.