Thermoformed trays.

Multi-chamber trays.

Multi-chamber trays are plastic packaging used mainly in the food sector, for example for microwave meals. Often the most important property of thermoformed multi-chamber trays is their sealability. Uniform, even tray edges are just as necessary for this as compliance with the article dimensions.

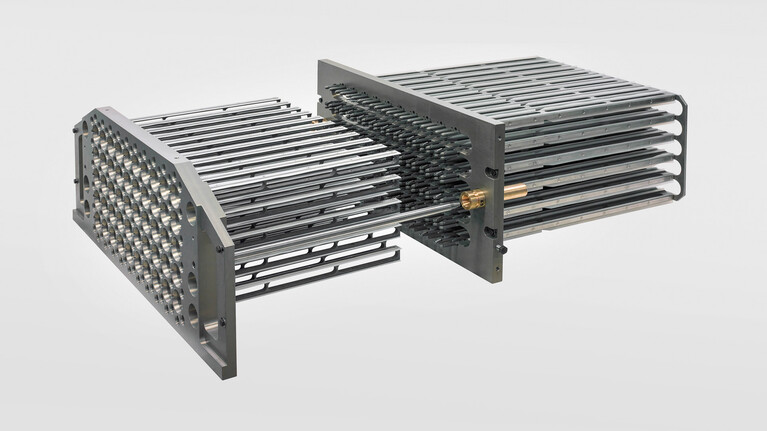

With thermoforming tools from Marbach, multi-chamber trays can be produced in a high-quality and efficient way. Sophisticated quick-change technologies also make it possible to realize various partitions and filling quantities with one mold.

Product attributes Multi-chamber trays.

Here you will find the matching technologies for the production of Multi-chamber trays.

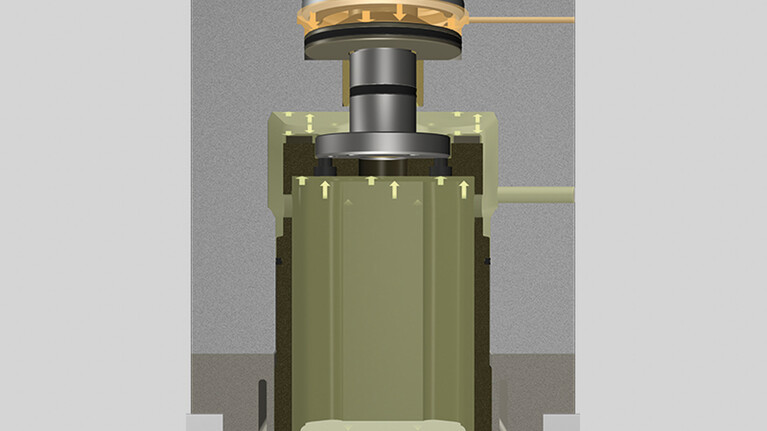

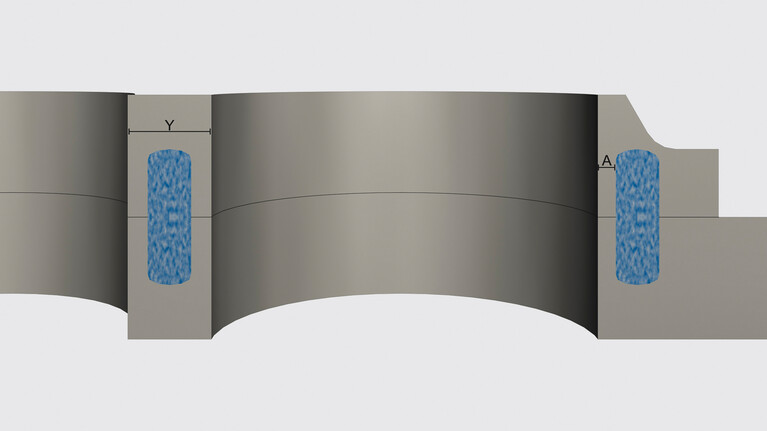

Our tilting tools offer you the best prerequisites for your thermoforming process of multi-chamber trays. MT|easy speed ensures high production speeds. Our sandwich technology stands for highly efficient cutting plates and the best cooling. The processing of powder metallurgical steel (PM) ensures a long service life, maximum performance, dimensional stability, dynamics and hardness. The 6-pillar guide allows the tightest tolerances to be used.

However, plug assist also has a significant influence on the thermoforming process. We have the right plug assist for your requirements. Mafox|P ensures that the plug can be changed quickly. The Mafox|2 quick-change system allows you to change the ejector bottom in seconds and with Mafox|F, clamp ring crowns can be optimally matched to the product to be manufactured. You control the pressure of the clamp force thorough the pressure-independent clamp rings in the thermoforming process. With our stacking systems, the formed multi-chamber trays can be reliably stacked in logs.