20. February 2017

Marbach evolves blanking technology. Blanking.

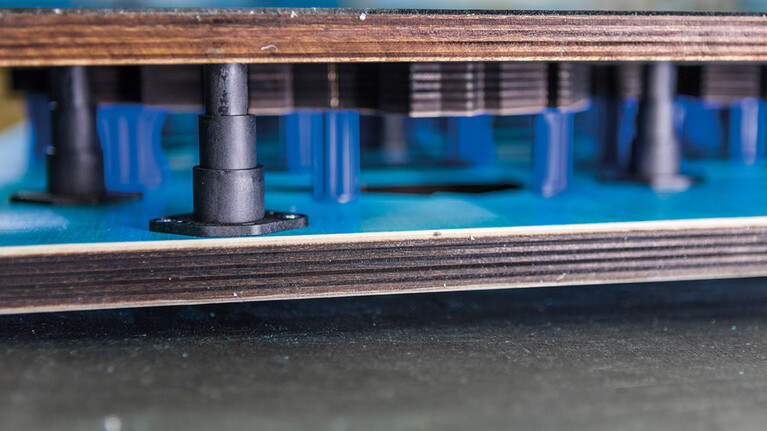

Marbach has further optimized its blanking technology. At FachPack 2016, Marbach presented for the first time its new blanking presser marbapusher|p. Since then it has enjoyed great popularity amongst the customers. Therefore, as of now, it will be used as a standard at Marbach. This means that all male marbablanker tools will be delivered with marbapusher|p in the future.

This system can be used for both presser plates and custom-shaped presser bars. Jan Brunner, Head of Business Development at Marbach: “Our challenge has been to develop a presser with a high degree of flexibility for the customer, that is durable and doesn’t take up a lot of storage space. Our marbapusher|p meets these requirements. From now on, thanks to its special design, a tool with a presser plate can be used in every kind of machine frame. So the waste grid is better fixed in position and higher machine speeds are possible. Moreover the marbapusher|p is being produced with long-life material which significantly increases life-span compared to other pressers in telescope version.”

Furthermore, there is a new adapter bar for the Marbach entry-level blanking tool – lightblanker. With this new adapter bar, existing blanking tools can be used on the new Marbach lightblanker frame quickly and easily.

Jan Brunner: “By now the majority of our customers count on our new blanking technologies. The lightblanker is characterized by its low weight and cost-efficient price. It is perfect for jobs where blanks have been separated manually before. For higher requirements, we have developed the marbablanker. It perfectly suits the operators' needs and allows a smooth production process. For very small blanks, we have the special nick-breaking solution. In this way we can offer our customers the right solution for every requirement.”