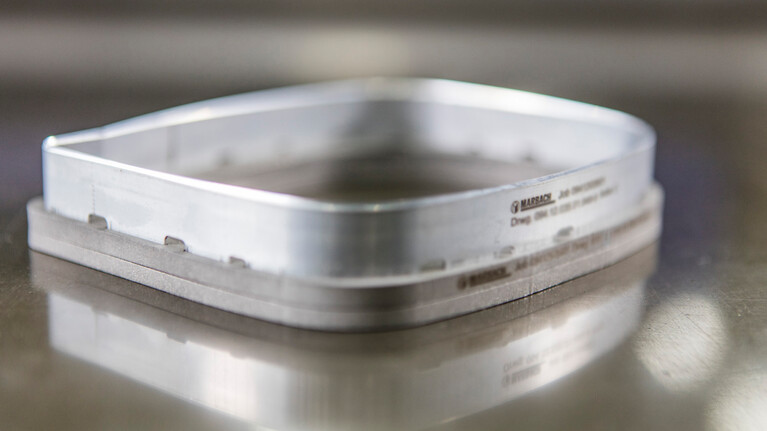

Thermoformed lids.

Lids with tabs, perforations, hinges

Easy, safe lidding and tightness are important attributes of thermoformed lids. Often there are additional requirements. A hole or a C-cut to ventilate the cup or bowl. Hinge functions with and without tear-open options are often used for solutions with tamper resistance or tamper-evident requirements.

A preprinted lid is often used for sales packaging where communication with the customer is particularly important. This high-quality decoration option requires precise registration and pre-centering.

Benefit from the know-how of our experts and let us advise you. Together we will find the optimal process for your requirements and define the appropriate tool.

Product attributes lids with tabs, perforations, hinges

Here you will find the matching technologies for the production of lids with tabs, perforations, hinges

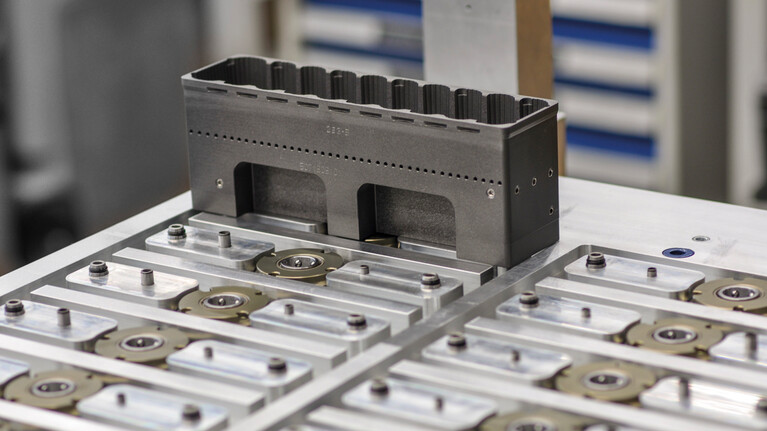

Our SR tools offer you the best prerequisites for your thermoforming process of lids with tabs, perforations, hinges - also pre-printed. The heart of the technology is the Marbach Silverline. This coated cutting line is extremely sharp and yet extremely pressure-resistant. It is also used for new measurements. The Flexi-Tab system consists of variable thickness key-stones in the anvil plate, creating the holding points under the steel rule.

Based on draw depth, the plug assist also has a significant influence on the thermoforming process. We have the right plug assist for your requirements. With 4M technology, we create “the best of both worlds”. A narrow plug assist supports a thin bottom, the wide plug brings stability to corners that are difficult to form. The 4M plug changes its contour during a stroke. And thus ensures an optimized material distribution. The Mafox | 3 system allows a forming bottom change within seconds.