1. September 2017

The importance of creasing forces for the production of cigarette packaging. Marbach solutions provide best performance.

Marbach is an expert when it comes to creasing in cigarette packaging. With its extensive range of products, Marbach offers solutions for the highest requirements.

For high-machine speeds in the packaging plant, creasing forces play a particularly important role. With the Marbach crease-plate technology, the creasing parameters – that are necessary for a smooth packaging process – can be reached simply and quickly. In combination with the Marbach creasing technology marbafold, 180-degree-fold become child’s play. The result: highest accuracy of the packaging and maximum productivity in the packaging machine. And even for round corner packaging with closely allied creases. But that’s not all: with the Marbach crease-bend-tester creasing values can be checked in detail. From the first material tests to examination during the production of cigarette packaging to the final inspections.

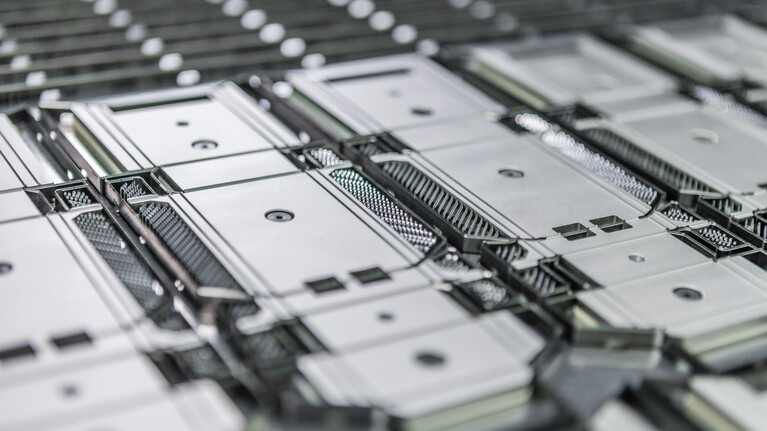

The crease-plate technology

In crease-plate technology, creasing comes first and cutting follows. Creasing doesn’t happen – as in the conventional production process – with creasing rules. Instead aluminum crease plates with creasing edges are used. They have an elastic base. They are therefore higher than the cutting rules. This makes it possible to first crease and then cut. This happens in one stroke in a conventional flatbed die-cutting machine. There are make-ready foils between the die-board and the elastomer, with which the crease-plates can be adjusted in their height quickly and easily and from the front if necessary. So the strength of the creasing shape, the folding resistance and spring back force of the creasing can be adjusted to the demands of the final customers without problems.

marbafold

Marbafold technology is used when it comes to reducing the reset force as far as possible. For cigarette packaging these are the so called 180-degree fold in the area of the top flap. Marbach can in this case, integrate the marbafold into the crease-plate-die.

Crease-bend-tester

The crease-bend-tester by Marbach is a quality control device with which the creasing values of folding boxes can be checked. It has been developed specially for this task and is used by various Marbach customers, paperboard producers and also brand owners. The samples, which are necessary for the test, can be die-cut simply and quickly with the marbapess, which has been developed for this purpose. They can then be tested without any time-loss.

Head of Sales international, Bernhard Reisser: “We offer our customers the best solutions for their highest requirements in cigarette packaging production with our diverse creasing technologies. For the optimization of their production and for highest performance in the packaging process.”

Those who would like to learn more about the topic creasing forces, may order a free English language brochure dealing with the topic quality control at Marbach. Inquiries should be sent by Email to: marketing@marbach.com