29. May 2017

Hygienically die-cut food packaging. With marbaclean.

The topic food safety plays an increasing role in the packaging industry. The warnings accumulate: bacteria in sesame, plastics in frozen herbs, metal in children’s breakfast, mineral oil in pasta, rice or cereals. The consumers become more and more insecure.

Brand owners, packaging producers and packer are dealing with the topic food safety and a reduction of sources of danger intensively. Because every recall action costs the brand owners money. It can be accompanied with longtime image loss for a product or the whole company with strong sales losses.

That’s why the food industry deals with this topic more intensively.

But one topic has been excluded of the public discussion: which risks does the packaging production process hold and how can they be avoided?

Excursion: How does mineral oil get into food?

There are many ways how mineral oil can get into food. The media shows mostly the way over the printing color or recycled board.

But substances can also migrate from cutting-dies: materials that encounter the die-cut paperboard can contain mineral oil or other questionable substances that transfer to the paperboard. Marbach has found a solution to avoid this with its newest tooling package.

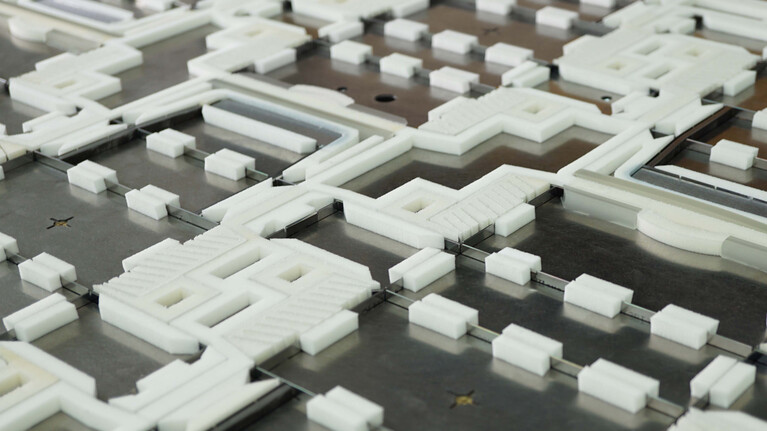

During the die-cutting process the paperboard gets in touch with the die-cutting machine, the cutting-die as well as the stripping and blanking tools. Or rather with the materials that are used for the production of those tools: the die-board, the cutting rules, creasing rules, rubbering and so on. The paperboard is being die-cut, stripped and the blanks are separated. There are three significant aspects concerning food safety:

1. The used tools shouldn’t loose any tool parts during the production process. Because this bears the risk that such a part ends up in the packaging.

2. Every single blank touches several parts of the tool package during the production process. If hygienically questionable materials are used in a tool, contamination of the packaging and therefore of the food can happen. This includes, for instance, mineral oil.

3. Cutting-dies are not produced under cleanroom conditions. Especially for direct packaging, the topic hygiene plays a very important role. Think about a sick employee that contaminates the cutting-die with bacteria. This tool later encounters directly the paperboard material and the food. An unappetizing idea.

Marbach has intensively dealt with the topic hygiene during the last three years. The outcome is a special hygiene tool package that is called “marbaclean” by the company.

The market demands unobjectionable packaging

Why did Marbach start to work on the topic hygiene already in the year 2014? Jan Brunner, Head of Business Development at Marbach: “The consumers demand from our customers, the print shops, to sign declarations concerning the harmlessness of food packaging. Our customers forward this to us. As a pioneer in innovation we think it’s our duty to deal with such topics. In this case the result is our tool package marbaclean.”

Harmless material

marbaclean is a tool package with harmless material. All tool parts that can get in touch with the paperboard are suitable for the food industry. That’s why when using a marbaclean tool it can be avoided that questionable substances – such as mineral oil – migrate from a material component of the cutting-die to food packaging. The materials of the maraclean tool package are certified by the ISEGA (independent verifying and certifying institution).

Special cleaning and test procedure

But not only the usage of specially certified materials characterize the new Marbach tool package. Furthermore there are additional cleaning procedures and audit standards in the production of marbaclean tools. Also the nicks, that normally are grinded into the rule, are cut at marbaclean tools, in order to avoid cutting dust. Special coating of the used materials also ensure hygiene as an appropriate factory equipment.

Safety mechanisms of the tooling package

Another important topic when looking at the new Marbach hygiene tool are loose materials. marbaclean tools are equipped with different safety mechanisms in order to eliminate the loss of tooling parts beforehand. These mechanisms include for example special assembly techniques, additional adhesion as well as longer rubber parts.

The latter ensures – even if there should be a loss of a rubber part – that this is quickly noticed or rather the rubbering stands out because of its size. And therefore doesn’t end up in the package. Moreover a rubber overview allows an examination of the completefullness of the tool before and after the production process.

Disinfection of all tool parts

Besides the already named criteria also the topic contamination through bacteria plays a significant role for the Marbach hygiene tool. Marbach has a procedure in use where all parts of the tooling package undergo a disinfection before the delivery – additional to the already named activities. Thereby bacteria and viruses are being eliminated. This procedure is optionally available.

Flexibility

Not all parts of the marbaclean package always have to be used. Depending on the customer, also only one component of the comprehensive package can be chosen. But for high requirements to hygiene, as for direct packaging, Marbach recommends the complete package. Because only with that the food safety, concerning the die-cutting process, can be ensured optimally.

Transport safety

All components of the marbaclean tooling package are – either with the extra option of disinfection or without – packed in a foil and additionally in a wooden package. So a damage or contamination on the transport way can be almost excluded with proper transportation.

Minimal extra charge for maximum security

Brunner: “Of course a tooling package in marbaclean version is a bit more expensive than a conventional tool. But if we only expect a quantity of 250.000 blanks, the additional cost for marbaclean is only 1 cent per packaging. Including the additional option disinfection. When I look at the trouble and especially on the image loss a company could possibly get through a large-scaled recall, this is nothing to speak of.”

Simple implementation into the production process

As of Marbach a change of the customers’ production is not necessary. The marbaclean tools can be used in normal die-cutting machines. The business only needs to meet the general prerequisites for the production of food packaging.

With marbaclean Marbach customers get a tooling package that fulfills technical as well as hygienic demands optimally.