13. April 2018

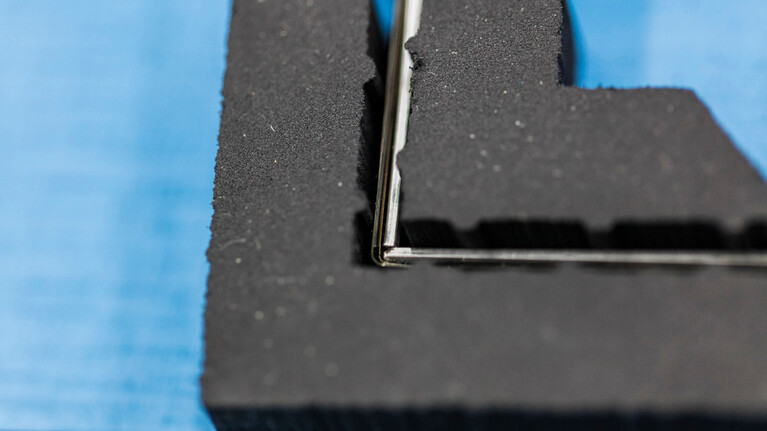

pure edge from Marbach. More than just clean visible edges. Multifunctional for corrugated board.

For some time now Marbach has been offering pure edge technology for achieving clean visible edges in corrugated board. Many customers are now using pure edge. It has been shown that this technology not only provides clean visible edges for corrugated board packaging, but is able to do much more.

Marbach developer Ingo Graham: "pure edge ensures clean visible edges for corrugated board packaging. We have known this for a long time. The success of pure edge and the feedback from our customers confirm this. Since we are enthusiastic about the technology ourselves, we have tested it on other applications. We have discovered that it is very versatile."

Knife protection in the edge area

The material to be cut often pushes the long straight edge knives away during the die-cutting process. The effect: due to the lateral material displacement, the cutting rule tip wears out relatively quickly at these points. This impacts the quality of the die-cutting result. The use of pure edge on both sides protects and stabilizes the cutting rules at the edges. The lifespan of the tool is thus extended and the cutting result significantly improved.

Stabilization of rule joints

In two-sided circumferential die-cutting, on narrow slots or on cutting contours, it is possible that the material which is being die-cut may squeeze the rules apart. This results in unwanted nicks. By using pure edge this can be prevented and the rule joints stabilized.

Increased service life

Pure edge can be used as a complete replacement of functional rubbering. Conventional functional rubber absorbs cutting pressure. In order to achieve good die-cutting results, this must be increased. But not with pure edge. Here the material is not unnecessarily tensioned and thus no additional cutting pressure is required. Pure edge should be used above all, in places where increased folding-spring-back forces in the material have to be avoided, but at the same time where no unnecessary traction forces should occur. As with 180-degree package folding, or nearby cut-crease rules for yoghurt crates with little surrounding material. But also on rules with transport nicks.

Solution for narrow areas

Depending on the requirements, pure edge is possible in widths ranging from 0.5 mm to 3.0 mm. This means that the technology can also be used in narrow places where there is simply no room for profile rubbering.

wear-resistance

pure edge is made of steel. Compared to rubber, this is very wear-resistant and has an extremely long lifespan.

With pure edge, Marbach offers a technology that can be used in a variety of ways and which not only stands for attractive optical corrugated cardboard packaging, but also for long tool life.