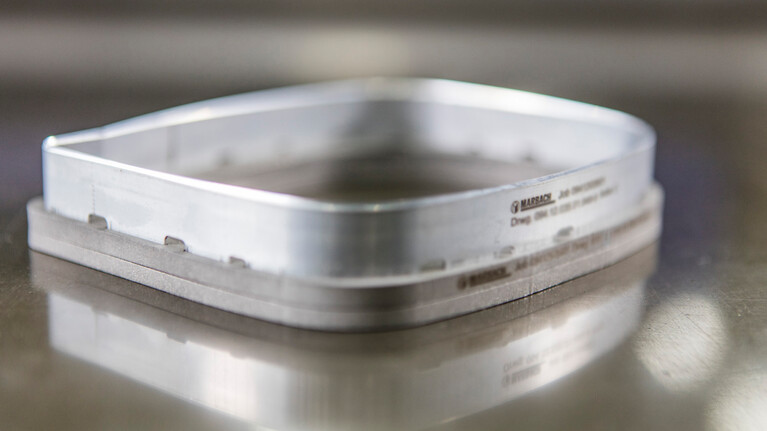

Thermoformed trays.

Meat MAP Trays.

Meat trays produced with Marbach thermoforming tools are characterized by their good processability. Flat sealing edges, well-formed contours and sufficiently stable corners are the most important criteria for meeting your customer requirements. Only flat sealing edges allow a fast, mechanical sealing process, and the stability that is achieved by means of reinforcing ribs is greater, the better they are shaped.

The part weight is often determined by the thinnest point in the article. For this reason, we attach particular importance to the design and shape of the stacking contours and the article corners.

Produkteigenschaften Meat MAP Trays.

Here you will find the matching technologies for the production of Meat MAP Trays.

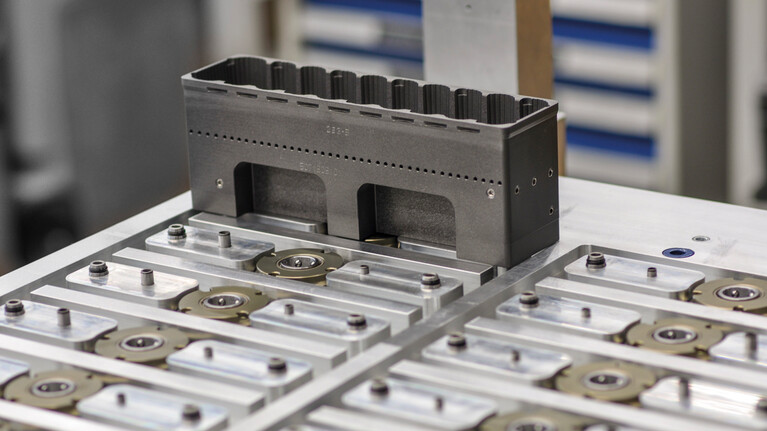

Our SR tools offer you the best prerequisites for your thermoforming process of meat MAP trays. The heart of the technology is the Marbach Silverline. This coated cutting line is extremely sharp and yet extremely pressure-resistant. It is also used for new measurements. The Flexi-Tab system consists of variable thickness key-stones in the anvil plate, creating the holding points under the steel rule.

Based on draw depth, the plug assist also has a significant influence on the thermoforming process. We have the right plug assist for your requirements. With 4M technology, we create “the best of both worlds”. A narrow plug assist supports a thin bottom, the wide plug brings stability to corners that are difficult to form. The 4M plug changes its contour during a stroke. And thus ensures an optimized material distribution. The Mafox|3 system allows a forming bottom change within seconds.