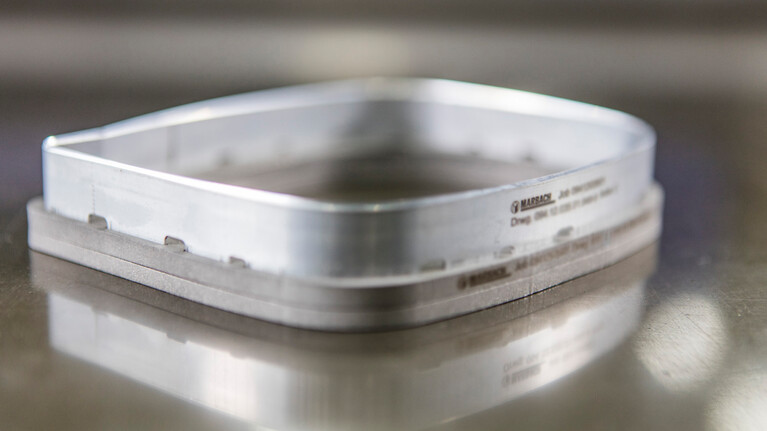

Thermoformed trays.

Fruit Trays

The task of fruit trays is to protect their contents during transport and storage, and to present the goods attractively to the customer at the point of sale. Often, particularly transparent packages are desired for this. The correct surface quality of the molded parts plays a particularly important role here.

With some packaging, care must be taken to ensure proper ventilation. This requires holes or slits at certain points and in defined locations. With our coordinated forming and punching tools, you can produce these trays efficiently and in the best quality.

Product attributes Fruit Trays.

Here you will find the matching technologies for the production of Fruit Trays.

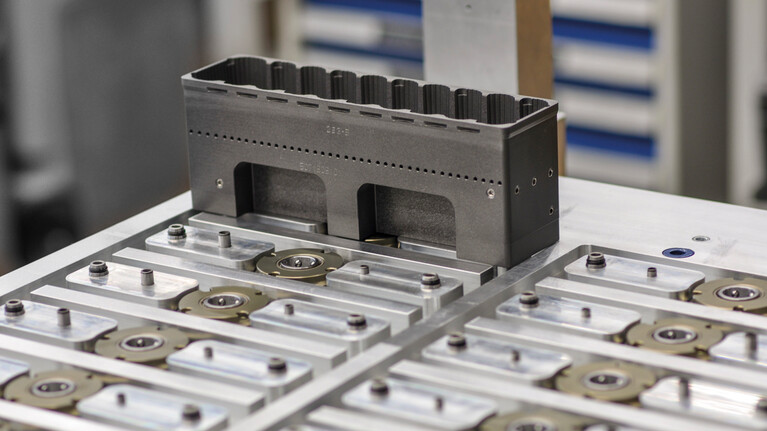

Our SR tools offer you the best prerequisites for your thermoforming process of fruittrays. The heart of the technology is the Marbach Silverline. This coated cutting line is extremely sharp and yet extremely pressure-resistant. It is also used for new measurements. The Flexi-Tab system consists of variable thickness key-stones in the anvil plate, creating the holding points under the steel rule.

Based on draw depth, the plug assist also has a significant influence on the thermoforming process. We have the right plug assist for your requirements. With 4M technology, we create “the best of both worlds”. A narrow plug assist supports a thin bottom, the wide plug brings stability to corners that are difficult to form. The 4M plug changes its contour during a stroke. And thus ensures an optimized material distribution. The Mafox|3 system allows a forming bottom change within seconds.