Compact course Paperboard. Die-cutting and Finishing.

Course No. P-COMP-EN

Duration:

1.5

day/s

Location:

Marbach Academy

Karl-Marbach-Straße 1

74080 Heilbronn

Karl-Marbach-Straße 1

74080 Heilbronn

Cost:

1195

€

Description

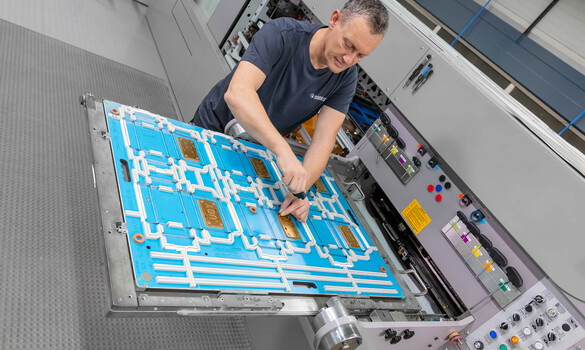

In this compact course on paperboard, participants receive practical insights into the paperboard die-cutting process in 1.5 days. The extensive practical part (approx. 60%) takes place at our die-cutting machine Eterna eCut 1060Elite, and the theoretical part (approx. 40%) in the modern premises of the Marbach Academy. Experienced technicians and trainers provide important information on the topics of die-cutting, stripping, blanking and finishing of paperboard. Of course, always at the current state of the art. The focus is on performance, product quality and productivity – with many practical tips for everyday work.

Content theory and practice

- A brief introduction to materials and their effects on the die-cutting process.

- Die-cutting machine. Safety instructions. Machine technology. Stations.

- Production-oriented packaging development.

- Presentation of tool package. Target state.

- Dieboard, rubbering, finishing and embossing, milled steel counter plate, reverse cutting.

- Profile and effect rubbering.

- Nicks, changing systems and marbanick|2+.

- Efficient tool package make-ready. Pressure balancing, cutting pressure and make-ready.

- Dynamic stripping and effective blanking.

- Calibration tool, universal sheet delivery, performance package, CONNECT|M.

- Challenges in practice, solutions, tips and tricks from practical experiences.

Target audience

This seminar is an advanced course for employees in the packaging industry – such as machine operators, designers, packaging developers, shift supervisors, production managers and plant managers – who want to refresh, deepen and broaden their knowledge. It offers the ideal opportunity to consolidate existing knowledge and develop skills in a targeted way. The aim is to improve performance and optimize workflows – an indispensable course for anyone who wants to expand their expertise.

After the training

The participants are up to date with the latest die-cutting technology:

- They will leave with an overview of the latest technology and how to use it to maximize productivity and improve the quality of their die-cut blanks and packaging.

- They will be able to effectively apply finishing technologies such as embossing or reverse cutting with minimal effort and downtime.