print preview

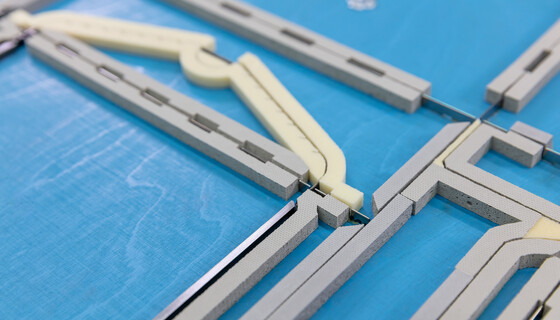

Opening mechanism

Reverse cuts.

BEAUTIFULLY PRESENTED.

A lot of packaging contains tear perforation. These can often interfere with the design and aesthetics. Or they may let dust into the package. Reverse cut technology can help in these cases. Both sides of the carton receive a half cut. For that reason the package stays sealed. And appealing. The result is an opening mechanism, which continues to look attractive. We at Marbach have used this technology for decades. We have mastered the reverse cut to perfection.

For special requirements, we have two versions of the height-adjustable anvil available for you: For corrugated board. And a split version for standard folding box tools.

But of course we are experts in all other perforation mechanisms as well. So that you will always produce what your customer expects.

- Optimal opening mechanism

- Dust-tight packaging

- Functional and beautiful result.