print preview

Special technologies.

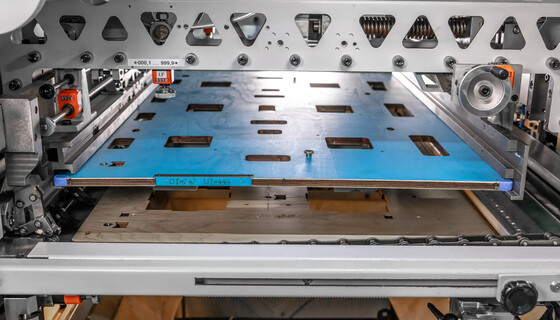

calibration tool package.

With the calibration tool package, you can now adjust the components of your die-cutter faster and more easily. Through this, the set-up and make-ready time can be reduced.

With time the zero position of the machine frame micro-adjustment is lost. This leads little by little to deviations. The stations’ die-cutting, stripping and blanking no longer fit 100%. Due to this, the set-up and make-ready times increase for every single job. And productivity decreases.

Through the calibration tool package, the three units: die-cutting, stripping and blanking, can be adjusted on, and to, each other. Thus the register cutting-die to counter plate and also the upper to lower part at the stripping and blanking unit, can be optimized. Everything fits precisely together once again. In this way the set-up and make-ready times can be reduced significantly, and performance increased.

This procedure should only be implemented by qualified personnel. For support, die-cutting machine manufacturers can also become involved.