print preview

minimal set-up times

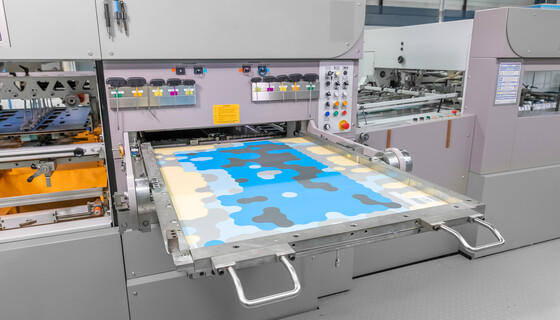

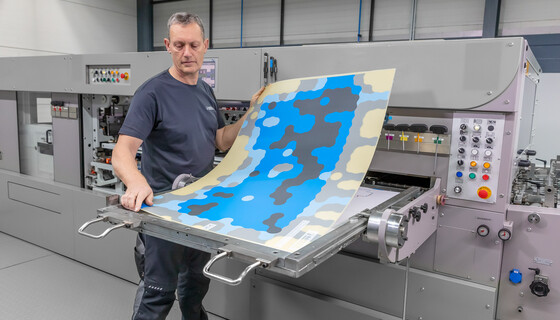

Digital zone levelling DZL|plate

The highest level of patching.

The die cutting machine is subject to wear-related deviations. This is not unusual. But for you this means, that with every job, you have to do a labor intensive zone make-ready. Marbach has the optimal solution for you. Digital zone levelling. All you need from us is a special grid die and a pressure sensitive foil. Make an impression. And send the foil back to Marbach. We will calculate the height profile of the machine. And print it onto a vetronite plate. Individually made for your machine. Levelling out the height deviations of the cutting platen. For machines in all formats, for large-format corrugated machines, there is the DZL|plateXL.

- levelling of machine-related deviations

- save make-ready time by avoiding an additional zone make-ready

- quick and easy to do

Calculator digital zone levelling

machine cost per hour

euro

number of new make-readies per month

piece

time savings for each new make-ready

minutes

time savings per month

hours

potential savings per month

euro

Investment digital zone levelling

paid off after

months