6. September 2017

Efficient stripping process. Marbach solutions for best performance.

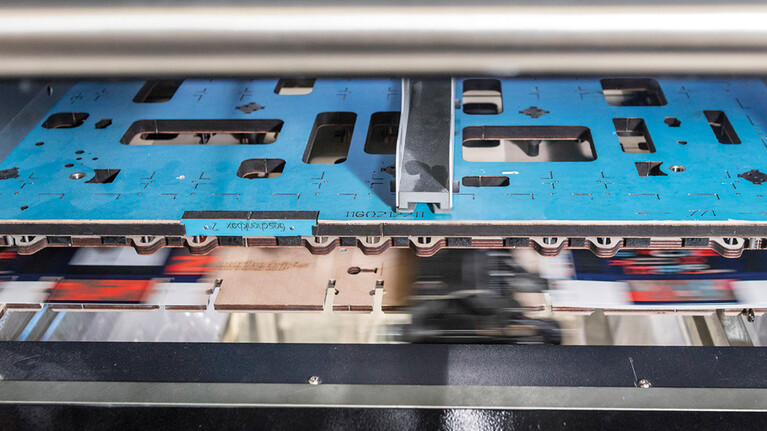

Marbach is still on the path to success with its premium stripping tool, the masterstrip|plate. During the last months this special stripping technology has significantly increased its percentage share of sales in all stripping tools. But why has this Marbach technology become so popular?

Jan Brunner, Head of Business Development at Marbach: “In our opinion, stripping by setting lower pins generally takes a backseat. This is also because die-cutting machines can and should run at higher speeds. With this, stripping with lower pins reaches its limits. The trend is increasingly moving towards dynamic stripping. And with high demands on waste-freeness and machine speeds, the masterstrip|plate is the tool many of our customers choose.”

The male stripper of the masterstrip|plate is equipped with a presser plate and a special sheet lifter. The presser plate straightens the sheet and ensures that the waste is fixed equally during the stripping process. The sheet lifter marbafly supports the smooth transport of the paperboard sheet during the stripping process. So it not only becomes safe with regard to machine stops, but can achieve very high machine speeds and almost waste-free production.