20. April 2017

New technology. For reduced make-ready times when reverse cutting.

Marbach has optimized its reverse cutting technology. With the new height-adjustable anvil, customers can now adjust anvil height of their cutting-die on their own, if necessary, and thereby save a significant amount of make-ready time.

Various food packaging has opening mechanisms. Reverse cutting technology is one possibility to provide paperboard or corrugated board packaging with a tear-off feature. Reverse cutting is the optimal solution wherever attractive appearance, complete dust resistance and opening features – that can be opened and sealed easily – are crucial.

Marketing manager Tina Dost: “When using the reverse cutting technology, highest precision is vital for optimal function. Because in reverse cutting the board is scribed on both sides – from the inside and outside of the package. This task becomes more difficult the thinner the paperboard is. With our new, height-adjustable anvil our customers can now save make-ready time and achieve more consistent results.”

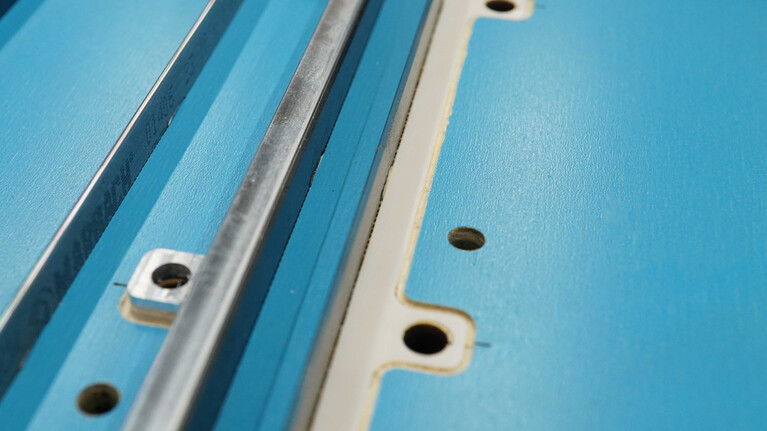

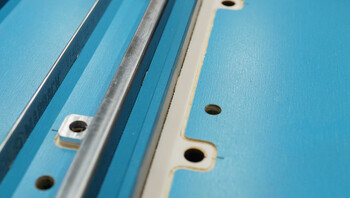

This new Marbach technology uses an aluminum block that is milled to shape. Its exact height depends on the thickness of the die-cut material. This aluminum block is not inserted into a laser cut contour in its complete height – as in conventional solutions – but in a height minus the die-board thickness and screwed onto the cutting-die from above. Foils are positioned underneath the anvil. The anvil can be adjusted in its height very quickly and easily through the removal or addition of these foils. Tina Dost: “In this way our customers can set-up their tool in the die-cutting machine much more quickly and precisely than with the conventional reverse cutting technology.”

Marbach offers this new reverse cutting option on the market with immediate effect.