22. May 2018

Safety during embossing. With Marbach technologies.

Marbach offers various solutions to ensure safe embossing of packaging. The Marbach standard already contains suitable solutions for many applications. In addition, Marbach has developed a further option ensuring even more safety in embossing.

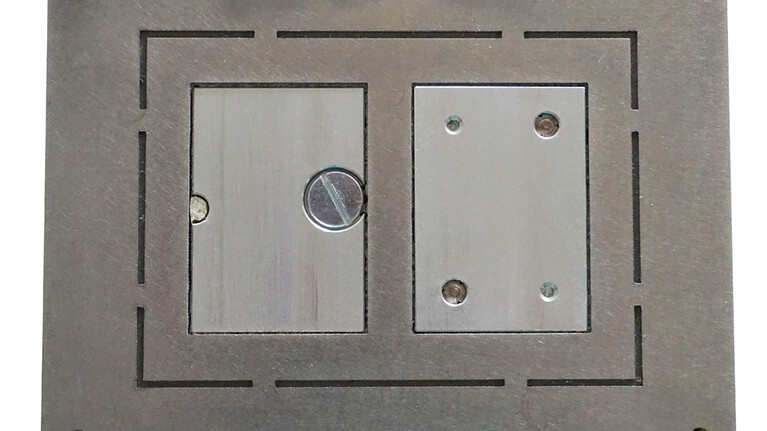

If packaging is not only die-cut, but also embossed, embossing clichés are then normally positioned on aluminum blocks. This means that the dieboard of the cutting-die contains cut-outs into which aluminum bases for the embossing clichés are inserted. This has the advantage that the embossing clichés have a very even base during the production process.

The aluminum substructure can be divided using a so-called Memopin, so that the embossing clichés can be set up quickly and easily from the front of the cutting-die. The tool can remain in the machine for make-ready. Also for die-cutting machines with closed machine frame. A make-ready from the back of the cutting-die is therefore not necessary.

Marbach development manager Klaus Rommel: "To ensure that the aluminum blocks are placed securely in the cutting-die and to avoid interruptions in production, Marbach provides two different ways of securing the aluminum blocks. With our standard method, the aluminum blocks are secured in the tool with two grooved pins. This prevents the aluminum blocks with the applied embossing clichés from falling out to the front. This type of protection is adequate in many applications."

However, in practice there are cases with particularly high demands or special requirements in which securing to the front is not enough for the operators. Then it is necessary to secure the aluminum block to an even greater extent.

Rommel continues: "For this reason, we looked for a solution that would ensure complete protection of the aluminum block against falling out either to the front or back. Our development has resulted in a completely new design of the aluminum block safety. With this version, the grooved pin is no longer required. Instead, a cut-out is milled into the aluminum blocks. The dieboard is given a "nose" at the appropriate point to attach the aluminum block to the dieboard and thus to prevent it from falling out on either sides".

This special version of the aluminum block safety device is designed for demanding requirements and offers the operator maximum safety. It can be used in the paperboard sector with multiplex, marbaplex and duramar tools.